Product

1500BPH 5 Gallon Water Filling Machine

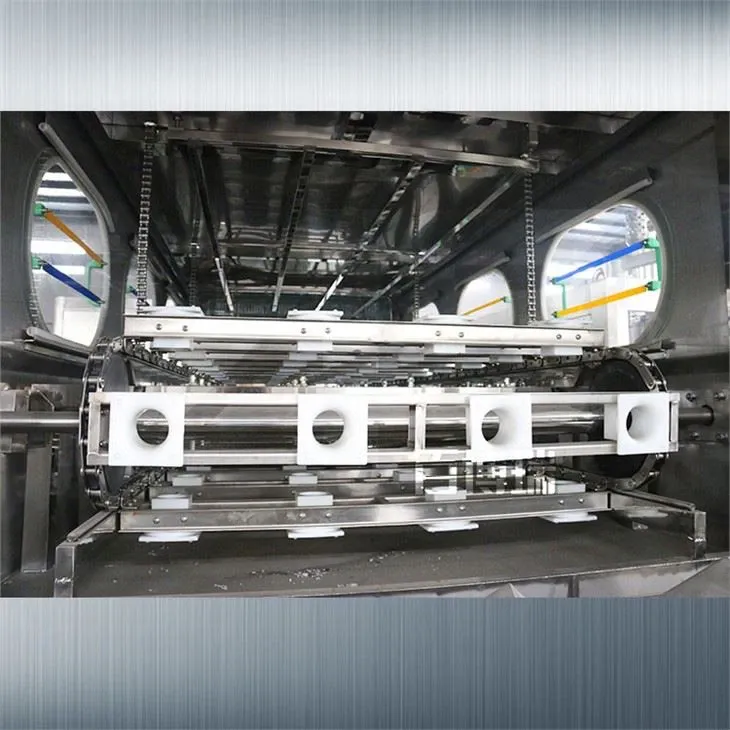

The floating rotary filling system is a linear filling mode. The filling nozzle is equipped with a stainless steel valve body.

Product Features

Product Description

The floating rotary filling system is a linear filling mode. The filling nozzle is equipped with a stainless steel valve body. The plug-in filling guarantees sealing and fast speed. It is equipped with a return line. The nozzle uses a spring-type top opening and soft action. . Independently fixed bottle holder, high working speed and density coordination efficiency, accurate positioning of water bottle into filling.

Decapping Machine

The equipment adopts Japanese Panasonic PLC control, imported SUS material, beautiful appearance and reasonable structure design. The machine has stable performance, accurate movements and low energy consumption. The empty bottle is placed on the conveyor chain, and the bottle is automatically sent to the place where the cap is removed. The automatic detection mechanism detects the signal at the cap puller and controls the cap puller to pull the bottle cap off. The pulling rate of the standard bottle cap is 100%.

Automatic Outside Brushing Machine

The barrel after the cover is moved into the outer scrubbing barrel machine by the sliding guide wheel. The outer brushing step of the rotating outer scrubbing barrel machine is composed of three parts. The first part is a specially designed brush shape to scrub the barrel mouth to remove dust and dirt from the barrel mouth. , Wash the dirt, the second part is composed of a special special brush in the shape of the barrel, which can wash the barrel powerfully to remove the dirt without hurting the barrel and the printed pattern. The third part is composed of a special brush at the bottom of the barrel. It can wash flat-bottomed barrels and concave-bottomed barrels. In the cleaning process, detergent is sprayed to make the dirt removal more thorough. At the outlet of the barrel, the clean water spray system will rinse the scrubbing detergent. The whole machine is closed without external leakage, high reliability and good stability. Equipped with overload protection, liquid level control, the water pump adopts the southern water pump, and all electrical appliances are Schneider products. The whole process is automatically controlled by the computer.

Automatic Washing Machine

The automatic cleaning and disinfecting machine is the main cleaning and disinfecting equipment in this production line. After the bottle is pulled out and processed by the pre-washing process, it enters the machine through automatic bottle loading for comprehensive internal cleaning and disinfection. The whole process is controlled by PLC, using imported frequency converter or pneumatic positioning system; accurate positioning and stable operation.

Our Company

Set up in 2009, Asiastar leads the market in the field of liquid bottling, blow molding, labeling, packaging machinery and process technology for water, juice, carbonated drinks, energy drinks, liquid, beer, edible oil, etc.

We can customize liquid production lines according to customers' demand. Every customer is the result of our proven experience and innovation. We continually focus on providing customers with advanced technology, engineering and facility that are designed with one motto in mind: Ensure you to reach business goals with most optimized planning