Product

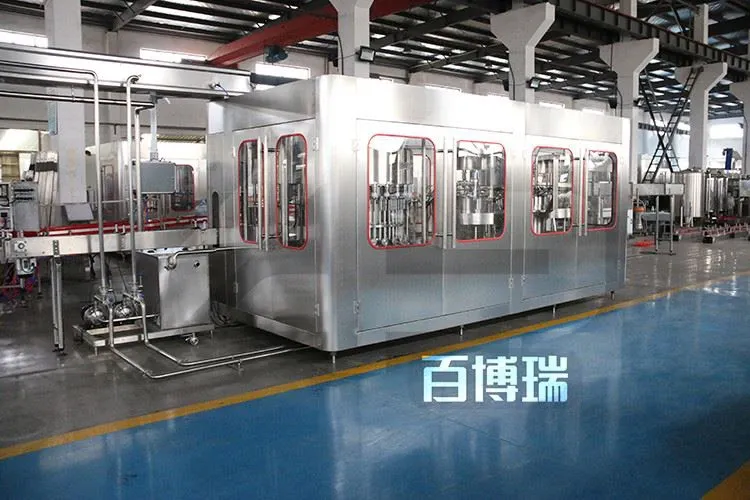

2000BPH 5 Gallon Water Bottling Machine

The filling machine is composed of the transmission system, the in and out barrel system, the filling system and the cover system;

Product Features

Product Description

The filling machine is composed of the transmission system, the in and out barrel system, the filling system and the cover system; each filling valve is equipped with flow control to ensure the stability of the filling pressure, so as to ensure the stability of the filling in various situations; it is equipped with frequency conversion control device and the filling fine adjustment device, with stable filling, high speed, high filling accuracy, no leakage and low liquid loss; all parts in contact with the product water (including the filling valve, etc.) are all made of food grade high-quality stainless steel materials and polished with no dead angle mirror surface, which is easy to clean; the filling valves are all free of dead angle, equipped with blowout prevention and return device, and equipped with closed recycling filling residual water device; the filling machine is of full sealing structure, with good sealing performance of the whole system and no overflow, and all observation windows are installed with plexiglass.

Rotary Capping Machine

Automatic Cap Elevator

-

Machine model: AS-100

-

Technical parameters:

-

Bottle form: mainly based on the physical products provided by the customer (or according to the bottle shape drawing of the customer)

-

Label size: mainly based on the physical products provided by the customer (or designed according to the bottle type drawing of the customer)

-

Production speed: 50 BPM (round bottle / filled / label length less than 150 mm in full set)

-

Applicable bottle diameter range of cutterhead: ? 50 ~ ? 95 mm

-

Applicable label length: designed and manufactured according to the label length provided by the customer (including 5mm blank section)

-

Applicable label thickness 0.035 ~ 0.06mm

-

Applicable label material: PVC / PET / OPS

-

Applicable inner diameter of label tube: 5 "~ 10" (inner diameter of label tube is 76mm)

-

Power supply: 3-phase 380V, 50Hz

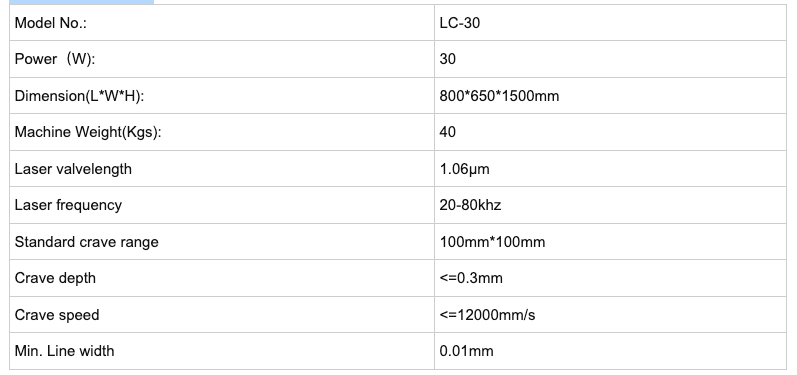

Laser Code Machine

Technical Parameter

Plastic Bag Packing Machine

By adopting the technology of straight-line conveying and barrel passing, the automatic film wrapping is realized, the production efficiency is improved, and the labor cost is saved.

Palletizer

In view of the increasing shortage of labor force and the shortage of labor resources in various medium and large drinking water purification plants, we have invested a lot of manpower and material resources in the development of five gallon bucket water automatic stacking equipment through the actual investigation of most drinking water manufacturers and the requirements of some customers. The equipment covers a small area and has low operating cost. 1500-2000 barrels of five gallon water bottles can be stacked into three layers (4 * 4 = 16 barrels per layer) as required to facilitate transportation and storage. The whole equipment can be easily operated by only one person, which reduces the labor intensity of employees and the staffing of the whole production line to the greatest extent.

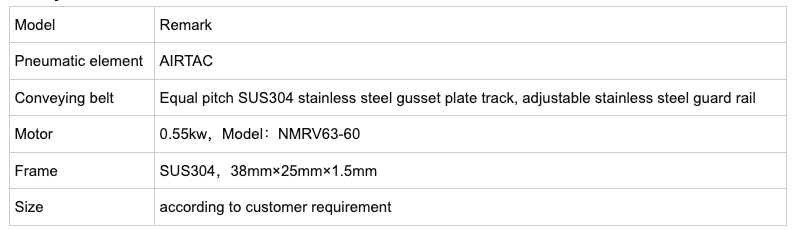

Conveyor