Product

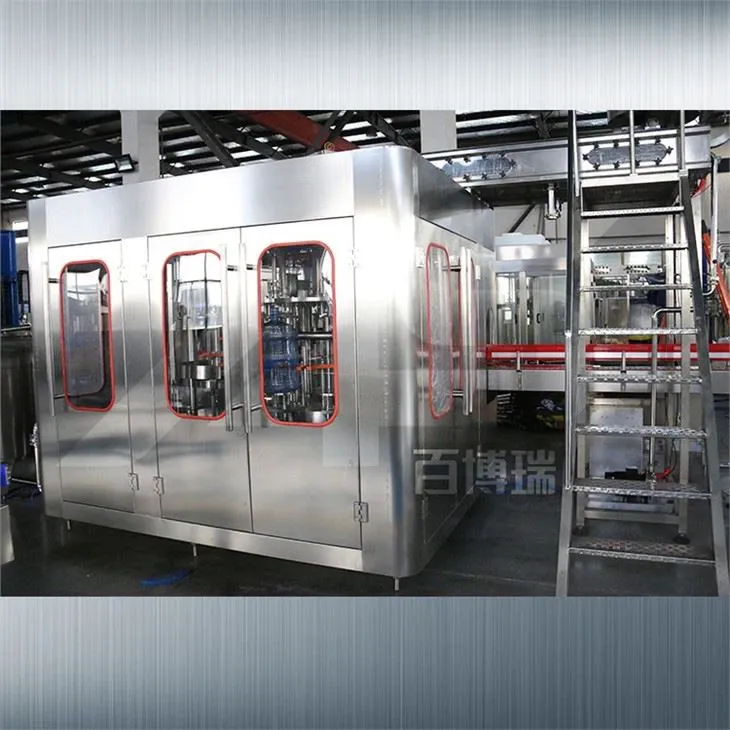

3-5 Gallon Water Filling Machine

The automatic detection mechanism at the Cap puller detects the signal and controls the Cap puller to pull off the bottle cap. The cap removal rate is 100% with standard bottle.

Product Features

Decapping Machine

Put the empty bottle on the conveying chain, and the bottle will be automatically sent to the Cap puller. The automatic detection mechanism at the Cap puller detects the signal and controls the Cap puller to pull off the bottle cap. The cap removal rate is 100% with standard bottle.

Outside Brushing Machine

After the cap is removed, the barrel is led into the external brush machine by the slide guide wheel. The brush step of the rotary external brush machine is composed of three parts. The first part is a specially designed brush to clean the unclean dust, soil and dirt at the barrel mouth. The second part is composed of a specially designed brush for the barrel body to brush the barrel body strongly to remove the dirt without damaging the barrel body and the printing pattern. The third part is composed of a special brush for the bottom of the barrel, which can not only wash the flat bottom barrel, but also wash the concave bottom barrel. During the cleaning process, the detergent is sprayed to help remove the dirt more thoroughly. At the outlet of the machine, the clean water spray system will wash the detergent.

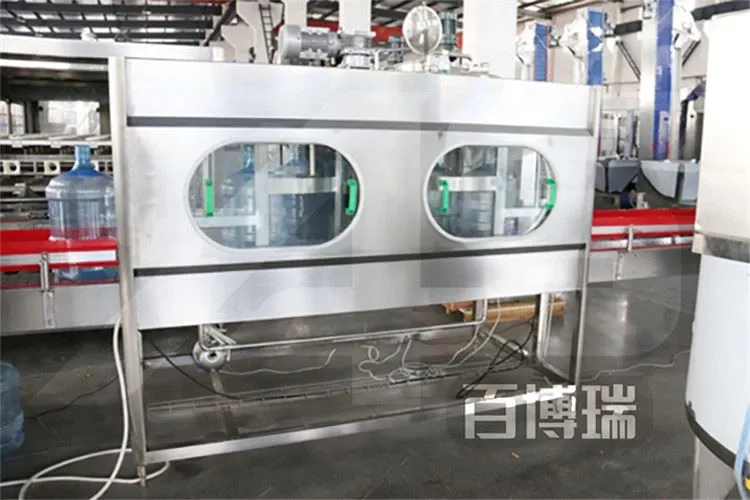

Inside Brushing Machine

It is mainly composed of a barrel pushing mechanism, a rotating shaft mechanism, a barrel outlet mechanism, a high-pressure washing mechanism, a control system, etc. It can carry out a three-dimensional all-round washing inside the bucket and is currently the best choice for bottled water production enterprises. When the five-gallon barrel is in contact with the high-pressure spray head, the spray head moves up and down, and the auto-movement of the barrel achieves the effect of scrubbing. The barrel neck, bottle body, bottle bottom and other parts can be fully cleaned. Dirt in the barrel. The whole is made of high-quality stainless steel, which is corrosion-resistant and easy to clean. The main electrical components are all famous brand products. The machine is beautiful in appearance, compact in structure, high in working efficiency, stable and reliable in operation, and high in degree of automation.

Rinsing Machine

Automatic washing Sterilizer, is the main washing and disinfection equipment in this production line. After cap pulling and pre-washing, the barrel/bottle enter the machine through automatic bottle elevator for comprehensive internal cleaning and disinfection. The whole process is controlled by PLC, using imported frequency converter or pneumatic positioning system; the positioning is accurate and the operation is stable.

Rotary Filling And Capping Machine

This machine is the fourth generation compatibility new type unit developed by our company through many years of production experience, repeated absorption of domestic customer feedback information and reference of international advanced technology. The machine adopts compatible system. The measuring filling valve is suitable for different bottle types of different sizes. It can perfectly solve the problem of different bottle type capacities. It is suitable for 3L-20L and various capacities of recovery barrels. Simple operation, quick replacement, multi-purpose machine for users to improve equipment utilization, save time, space and personnel.

Automatic Bagging Machine

The machine adopts the straight conveying technology to realize automatic film wrapping, improve production efficiency and save labor cost.

Gantry Palletizer

This machine is fully automatic control, automatic pick and place tray, automatic barrel feeding, automatic grab bucket palletizing, automatic pick and place partition, automatic stacking. During production, manually pull a tray to the designated delivery position, and the bagged barrel water are transported by the conveyor, and are arranged into 1 row by a pneumatic mechanism (4 barrels per row, which can be customized by the customer). Pick and place on the tray, code one layer and manually put a partition on the stack, then repeat the process. After palletizing, stack out manually (fork with forklift), then repeat the palletizing operation. Single-person operation, simple and easy to maintain.

FAQ

Q1:Would you have a discount if l have a large order?

A: Yes we could offer different discount according to your order quantity.

Q2:Is there the products tested before shipping?

A:Yes, of course.

Q3:Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

Q4:Can you provide drawings and technical data?

A: Yes, our professional technical department will design and provide drawings and techical data.