Product

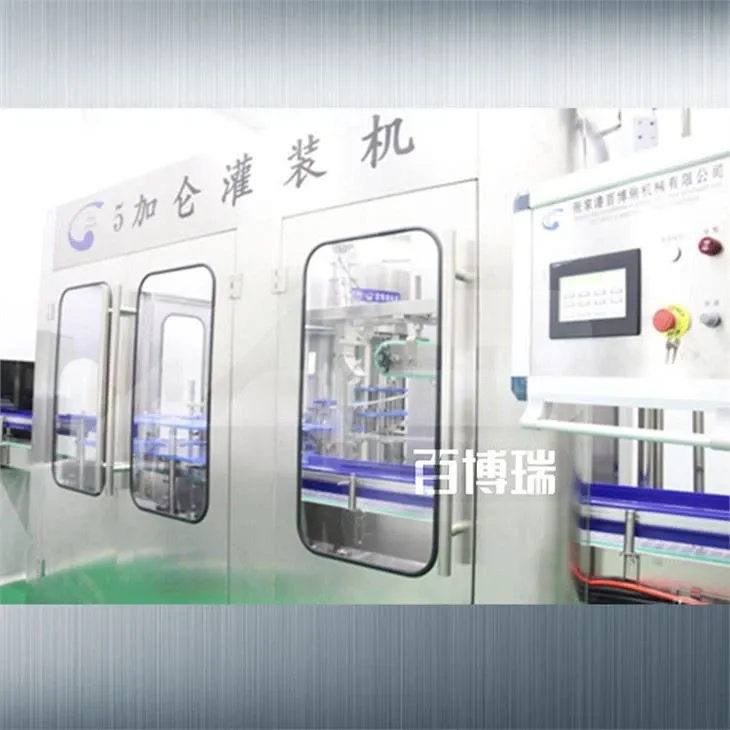

5 Gallon Bottling Water Machine

The filling machine is composed of a transmission system, a barrel in and out system, a filling system and a capping system;

Product Features

Product Description

The filling machine is composed of a transmission system, a barrel in and out system, a filling system and a capping system; each filling valve is equipped with flow control to ensure stable filling pressure, thereby ensuring stable filling under various conditions; equipped with frequency conversion Control device and filling fine-tuning device, stable filling, high speed, high filling accuracy, no leakage, low liquid loss; all parts in contact with product water (including filling valves, etc.) are made of food-grade high-quality stainless steel materials And it is mirror-polished without dead corners and is easy to clean; all filling valves have no dead corners, are equipped with anti-spray backflow devices, and are equipped with closed filling water recovery devices; the filling machine adopts a fully sealed structure, and the entire system has good sealing performance. Overflowing water, all observation windows are equipped with plexiglass.

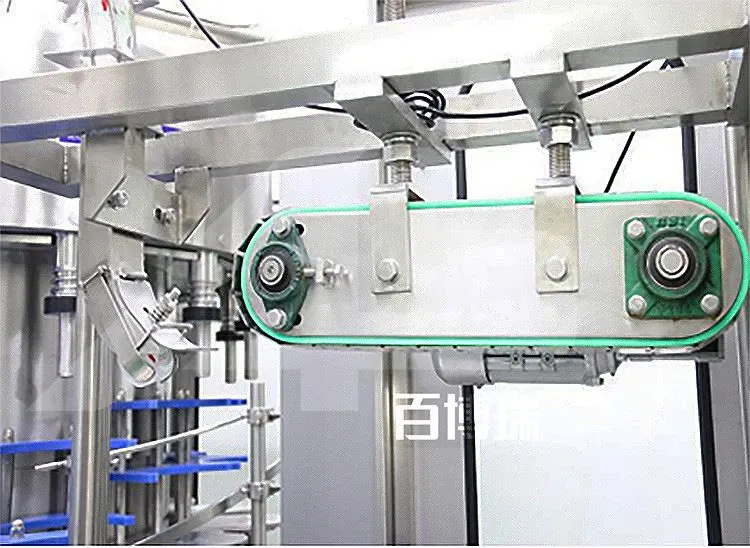

Chain Plate Sealing Machine

The chain-type cap feeder has a compact structure and the body is made of high-quality stainless steel. The machine adopts the principle of timing cap lifting. When the cap amount is insufficient, the detection switch in the cap container sends a signal, the cap lifting machine starts to work, and the cap feeding machine works. It will stop automatically after a fixed time (about 1 minute). The lid holder is connected to the rotary lid sorter. The machine adopts the principle of automatic lid lifting through the turntable. When the lid volume is insufficient, the detection switch in the lid holder sends a signal and the lid feeder starts to work.

Cap Elevator

The bottle cap is lifted into the cap sorter by the conveyor, and the cap sorter

The device smoothly slides into the disinfectant spray guide, the disinfectant

The pressure generated by the pump passes through the nozzles to each point inside the cover

Spray, while pushing the cover forward by the water jet,

After the disinfectant spray is finished, enter the sterile compressed air

In the spray area, blow dry the sterile water in the cover and rely on aseptic

The compressed air jet force sends the cover into the sterile water jetting area,

The cover is also sent into the airtight guide by the spray force of sterile water

The rail is sent to the sealing machine.

Light Checker

The LED light inspection box adopts LED light source and imported high-transmittance light guide plate with uniform light intensity distribution, no dark areas, no flicker, and stable color temperature, making the screen brighter and softer. It can be widely used in food, medical, electronics and other fields. It is especially effective for detecting color, turbidity, water leakage, and visible objects.

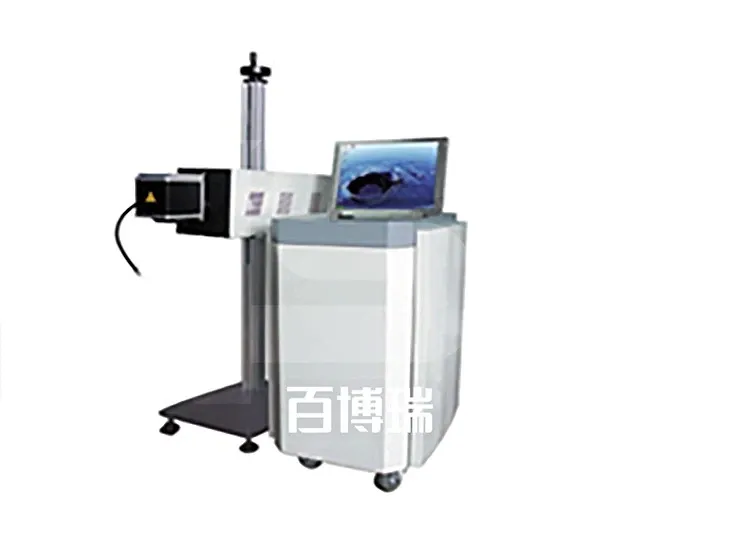

Laser Code Machine

The laser imported from the United States and the advanced polarizer system ensure excellent coding quality and high-speed output. The entire laser system integrates a touch interface, an induction sensor and a lifting frame. The structure design is exquisite and compact, so it can be easily installed in a small space. The product is suitable for small and medium-sized enterprises and customers with relatively slow product lines. The products are mainly used in daily chemical, food, beverage, medicine and other medium and low speed coding.

Automatic Bagging Machine

The automatic filming machine is one of the necessary equipment for the high-speed barreled production line. This machine is superior to the traditional manual bagging machine. It only needs to put the film into the machine without manual operation. The filled barreled water enters the sleeve. The film machine, the electronic eye gives the machine a signal, every time the barrel passes, the machine works once to glue the film together. Fast speed and high efficiency.

Payment Term

- Payment Term:

- 30% T/T in advance as deposit , and the balance be cleared before shipment ;

2)Sample Provide

-

The customer should supply no less than 50pcs samples for each kind of bottle and 200 pieces samples for each kind of cap within a week after the contract is signed

-

If customer without bottle sample yet, need provide the bottle & capper drawing with full dimension details

- Delivery & Packing

-

Delivery Time: 30 days after get the bottle & Caps sample or get the bottle & cap dimension

-

Coming Document:

? Machine Quality Guarantee

? Complete set install & maintain instruction Book in English language

? Complete Document for customer clearance

- Packaging requirement:

? The special packaging box is according to the immunity standard in China?it suits for long-distance transport, damp proof, rustproof, land way and seaway.

? Transportation ways: Ocean transportation

- Install in Spot

- If our Engineers install in spot

? Installment USD80/day. Person as allowance

? Training fee is free for customer’s workers within the installation period

? The tickets from China to the customer factory and return paid by the customer

? The visa cost, local housing , food, and transfer cost at customer factory paid by the customer

- Mechanical Warranty

-

Offer 12 months maintenance period to the problem that caused by our design, manufacture and the material quality, and offer the relevant parts and effective service for free for above reason.

-

Come with one year’s recommended spare parts