Product

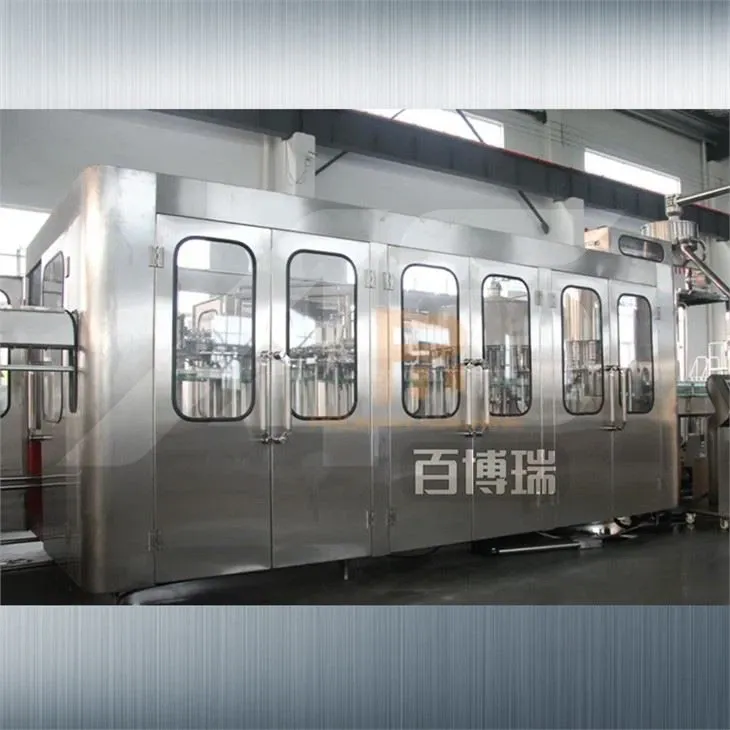

10000BPH Carbonated Drink Filling Machine

Carbonated beverage filling machine is used to produce polyester bottled soda water and other carbonated beverage machinery.

Product Features

Product Description

Carbonated beverage filling machine is used to produce polyester bottled soda water and other carbonated beverage machinery. The RFC series Wash-filling-capping 3-in-1 unit:Beverage Machinery can finish all the process such as washing bottle, filling and capping, it can reduce the materials and outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

-

The 3-In-1 Carbonated filling machine is used for carbonated drinks filling.

-

The machine contains washing filling and capping with complete automation.

-

The machine suitable for aerated water filling into polyester bottles and PET bottles.

-

It can be used for all kinds of bottles.

-

The bottleneck blocking makes the process of changing bottles easy by only adapting the height of convey or chain.

-

The filling process adopts the micro-pressure technology, which makes filling process faster and more stable.

-

Compared with other equipment of the same kind this machine possesses a better quality and thus enjoys a high ratio of function against price.

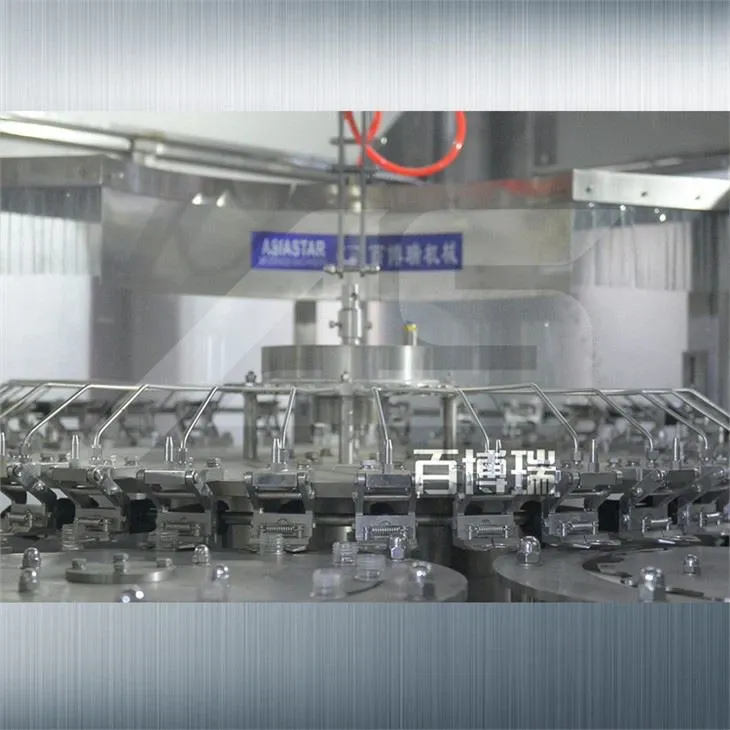

Rinsing Part

-

Enhanced food safety: Stainless steel 304/316L for all components in contact with your beverage

-

Optimum uptime: 30 % reduction in changeover and maintenance downtime

-

Sustainable solution: Reduced filler enclosure and servo motors reduce resource consumption

-

Hygiene improvement through volume control and contactless filling

Filling Part

-

304/316 Stainless steel high precision filling nozzle

-

Filling volume adjustable in fine rank, same liquid level after filling

-

All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

-

304/316 stainless steel filling pump

-

Efficient spray nozzle rinse thoroughly and save water for flushing

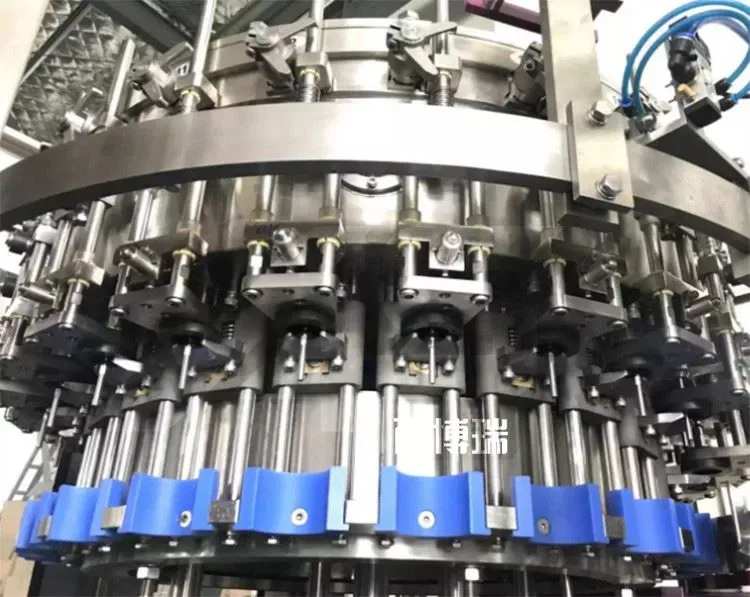

Capping Part

-

Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

-

All 304/316 stainless steel construction

-

No bottle no capping

-

Automatic stop when lack of bottle

-

Capping effect is stable and reliable ,Defective rate ?0.2%

Payment And Delivery

- Payment Term

- 30% T/T in advance as deposit , and the balance be cleared before shipment ;

- Sample Provide

-

The customer should supply no less than 50pcs samples for each kind of bottle and 200 pieces samples for each kind of cap within a week after the contract is signed

-

If customer without bottle sample yet, need provide the bottle & capper drawing with full dimension details

- Delivery & Packing

-

Delivery Time: 30 days after get the bottle & Caps sample or get the bottle & cap dimension

-

Coming Document:

? Machine Quality Guarantee

? Complete set install & maintain instruction Book in English language

? Complete Document for customer clearance

- Packaging requirement:

? The special packaging box is according to the immunity standard in China?it suits for long-distance transport, damp proof, rustproof, land way and seaway.

? Transportation ways: Ocean transportation

- Install in Spot

- If our Engineers install in spot

? Installment USD80/day. Person as allowance

? Training fee is free for customer’s workers within the installation period

? The tickets from China to the customer factory and return paid by the customer

? The visa cost, local housing , food, and transfer cost at customer factory paid by the customer

- Mechanical Warranty

-

Offer 12 months maintenance period to the problem that caused by our design, manufacture and the material quality, and offer the relevant parts and effective service for free for above reason.

-

Come with one year��’s recommended spare parts

Packaging