Product

3-In-1 Carbonated Drink Filling Machine

This kind of complete set of drink filling machine combines filling and rotary capping functions in one unit,is a fully automatic and high efficiency liquid packing equipment.

Product Features

Product Description

1.This kind of complete set of drink filling machine combines filling and rotary capping functions in one unit,is a fully automatic and high efficiency liquid packing equipment.

2.It is suitable for packing carbonated soft drink ,beverage containing gas. Its performance is as following all parts,for instance, filling valve, which directly contact medium are made of stainless steel or harmless material. So it conforms to the requirements of Food sanitation.

3.The line has features of unique design,new style, complete functions,multi-purpose, convenient in operation, beautiful construction, high automaticity.

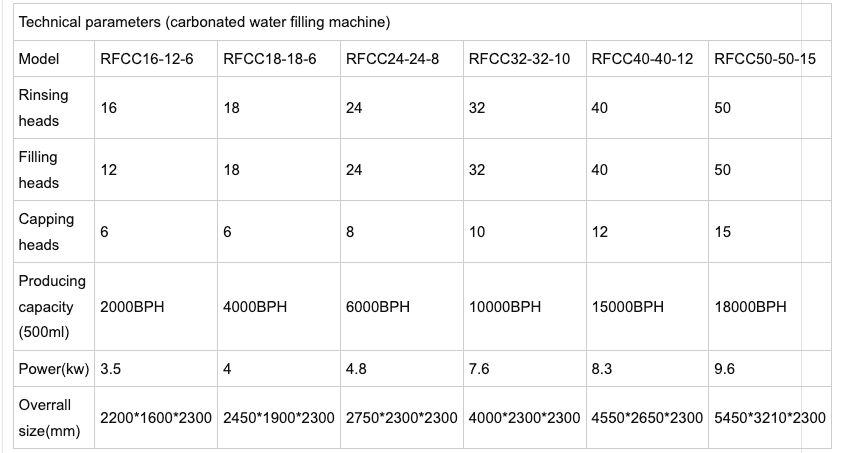

Technical Parameters (Carbonated Water Filling Machine)

Washing Part

-

Into bottle way is air conveyor direct connection with bottle dial.

-

All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.

-

304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

Filling Part

-

304/316 Stainless steel high precision filling nozzle

-

Filling volume adjustable in fine rank, same liquid level after filling

-

All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

Capping Part

-

Place with the capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

-

All 304/316 stainless steel construction

-

No bottle no capping

-

Automatic stop when lack of bottle

Auxiliary Equipment

Water Treatment System

-

Raw water tank + Raw water pump

-

Quartz sand filter + Active carbon filter +Sodium filter+ Precision filter

-

Reverse Osmosis (one level)

-

UV sterilizer

-

Finished water tank + Pure water pump

Carbonated Drink Prepare System

Carbonated Beverage preparing process

Syrup melting tank-- Syrup filter-- syrup cooler-- Beverage blending tank-- Double head filter-- freezer cooler-- CO2 mixing machine

Packing System

Light checker-- Bottle warmer-- Bottle dryer-- Auto sleeve label machine—Laser code machine-- heat shrink film packing machine.

Bottle Warmer

Function: After filling,the whole bottle is cool, once contact the air, the bottle outside wil be with condensing water. It will affect the following packing process, and bottle warmer will hot the bottles after filling ,and also rinsing the bottle outside.

Automatic Heat Shrink Film Packing Machine

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product.

About Us

Set up in 2009, Asiastar leads the market in the field of liquid bottling, blow molding, labeling, packaging machinery and process technology for water, tea, juice, carbonated drinks, energy drinks, liquid, beer,etc.

We can customize liquid food production lines according to customers' demand. Every customer is the result of our proven experience and innovation. We continually focus on providing customers with advanced technology, engineering and facility that are designed with one motto in mind: ensure you to reach business goals with most optimized planning.

Why Choose Us

(1)A to Z turnkey plant provider

(2)Fully automatic or economic solution optional

(3)10+ years of global market experience

Payment And Delivery

- Payment Term

- 30% T/T in advance as deposit , and the balance be cleared before shipment ;

- Sample Provide

-

The customer should supply no less than 50pcs samples for each kind of bottle, and 200 pieces for each kind of caps within a week after the contract is signed

-

If customer without bottle sample yet, need provide the bottle & capper drawing with full dimension details

- Delivery & Packing

-

Delivery Time: 30 days after get the bottle & Caps sample or get the bottle & cap dimension

-

Coming Document:

? Machine Quality Guarantee

? Complete set install & maintain instruction Book in English language

? Complete Document for customer clearance

- Packaging requirement:

? The special packaging box is according to the immunity standard in China?it suits for long-distance transport, damp proof, rustproof, land way and seaway.

? Transportation ways: Ocean transportation

- Install in Spot

- If our Engineers install in spot

? Installment USD80/day. Person as allowance

? Training fee is free for customer’s workers within the installation period

? The tickets from China to the customer factory and return paid by the customer

? The visa cost, local housing , food, and transfer cost at customer factory paid by the customer

- Mechanical Warranty

-

Offer 12 months maintenance period to the problem that caused by our design, manufacture and the material quality, and offer the relevant parts and effective service for free for above reason.

-

Come with one year’s recommended spare parts