Product

500ml Carbonated Drink Bottling Machine

The RFC seris carbonated drink filling equipment adopts bottle neck holding transmission technology to realize fully automatic bottle rinsing,carbonated filling and cap screwing.

Product Features

Product Description

The RFC seris carbonated drink filling equipment adopts bottle neck holding transmission technology to realize fully automatic bottle rinsing ,carbonated filling and cap screwing. It employs single cavity plunger type of fixing filling volume technique. It is equipped with CO2 accuracy pressure control, so that the liquid level is always stable. The application of alarm devices for bottle jam, bottle shortage, bottle damage, cap shortage, over loading etc. To ensure the quality of its production in several places. The machine obtains advantages of high reliability, high efficiency, high grade of automation and easy operation etc.

Soft Drink Filling Machine, Carbonated beverage Filling Machine.

-

Material: The material which contact directly with the liquid is the SUS304 (Food grade),made in China. The 3-in-1 is mainly used to fill pure water, Mineral water, carbonated drinks,wine etc.

-

This machine is mainly for filling carbonated beverage, like Feda, sprite, coca cola.and energy drink.

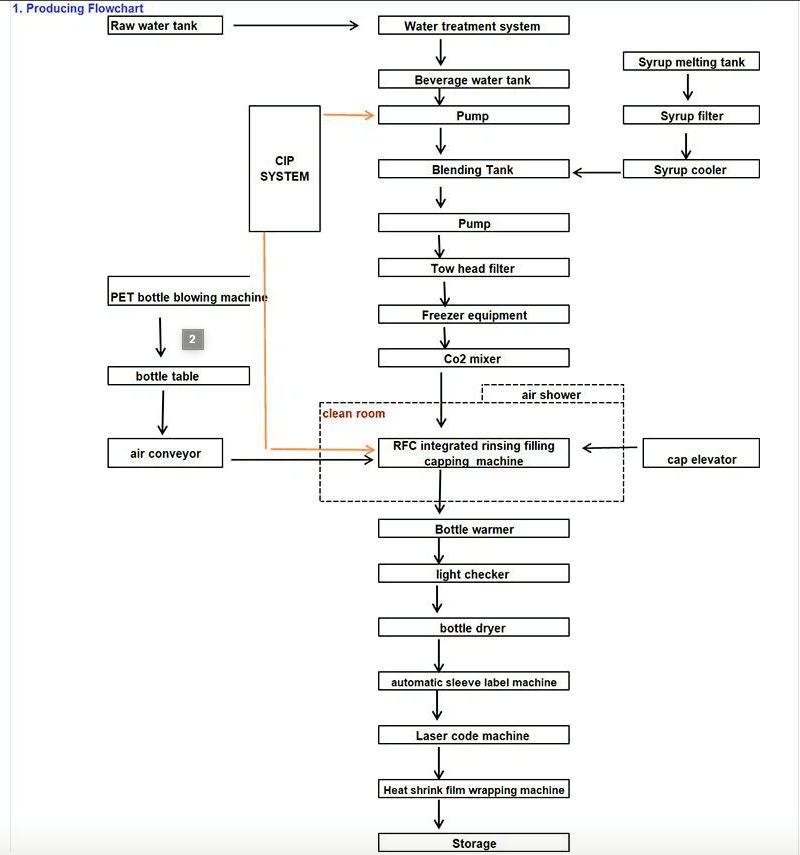

Producing Flowchart

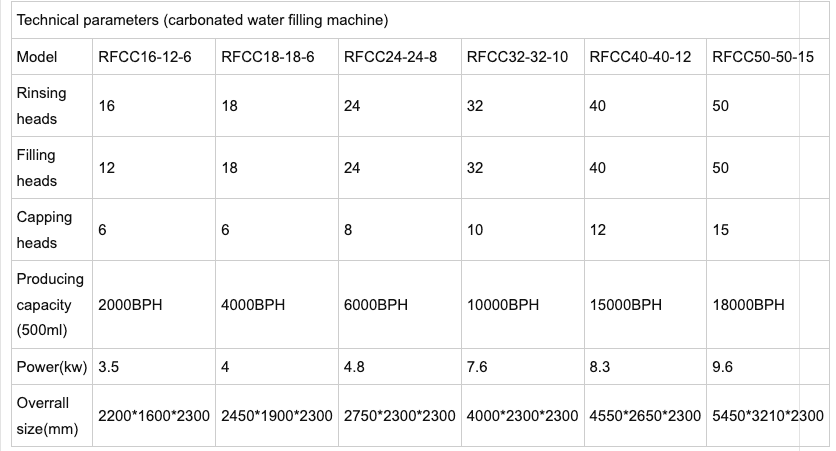

Technical parameters (carbonated water filling machine)

Rinsing Part

The new bottle is transported through the separation screw and starwheel by the clamp and turn over device; bottle neck is held upwords, after aseptic water rinsing, the bottle neck goes up and transported to another process.

The rinsing contact part and out cover adopt the stainless steel material

Open design gear driving

The bottle in place is equipped with pneumatic part, controlling the bottle, avoiding the falling down bottle come to the main machine

Water pipe of rinser is equipped with pressure gauge and pressure maintaining valve

Water collecting tray: recycle the rinsing water

lf no bottle or stop, rinsing stops; while it comes to bottle, it runs again

Filling Part

Adopt the guiding pole with cover function ;bottle held elevation desgin , ensures the complete seal between bottle neck and filling valve ,avoids the leakage.

Equip with the anti break device ;bottle break cleaning ,avoiding the next botte .

Equip with complete CIP cleaning function

According to different height , it achieves elevation automaticlly and equips with the high& low level safety protection .

Main drive adopt the gear drive with open design :high effeciency ,low nocie ,long life ,easy matainance ,full lubrication .

Adopts the stepless frequence inverter to control main motor rotation

Bottle guding system ,simple structure ,which can change the bottle size more easily .

Adopts the bottle held structure

PLC control , the default can be listed as block ,cap shortage and etc.

Filling machine: Adopt supporting structure of the bearings, simple and reliable structure, easy maintenance, smooth operation.

Filling pressure: A unique filling valve structure makes stable liquid shunt, to avoid foaming with the level correction.

On the orientation of the guide rod, the pre-mask function; bottle bottom hold structure enhance accurate sealing of the mouth and the filling valve, reducing the material leaks from the bottle.

Equip with the level sensor to ensure the filling stablity .

The key part and electric component adopt imported products.

Capping Part

Capper rotates through the speed reducer machine .The cap leaves the hopper under the centrifugal function .The exit is equipped with the cap reverce dvice ,when the reverce cap comes ,it is changed to the right direction ;the cap quantity is controlled by the photoelectric switch ,ensures the caping falling effect.

lf the container has the cap ,the second cap cannot go in ,which utilizes the cap .

And it is equipped with photo eletric switch on the slding trail ,when it tests that there is no cap ,it stops automatically

Capper is equipped with compensation function, reducing the bottle break rate.

lf there is only one standard crown cap in different size bottle, the capping mold doesn't need to be changed.

According to different height bottle shape, the capper can be adjusted automatically.

Certification

Our Company

Asiastar Beverage Machinery Co., LTD is a manufacturer specializing in the production and sale of liquid filling production equipment. The company has complete processing equipment, perfect technological process, strong technical force, excellent product development and design ability, rich production experience, etc. The company provides various services for the design, manufacture, installation, maintenance, technical improvement support, technical consultants, etc. of filling production equipment for drinking water, pharmaceutical, and chemical manufacturers. The company specializes in the manufacture of liquid filling equipment for disposable barrels particularly. We have rich experience, reliable quality and good effect in equipment manufacturing and engineering construction. With the rapid development of science and technology, we adhere to the principle of precision manufacturing and perfection first in terms of functional design, material selection, welding technology, process quality control and even appearance beautification. Each process has been carefully planned and required and the products are sufficient to meet the hygienic inspection standards for the production of drinking water, medical preparations etc.