Product

500ml Carbonated Drink Filling Machine

Adopts the negative pressure filling which we specifically design for CSD filling, it ensures minimal loss of CO2 from the product

Product Features

Product Description

-

Adopts the negative pressure filling which we specifically design for CSD filling, it ensures minimal loss of CO2 from the product

-

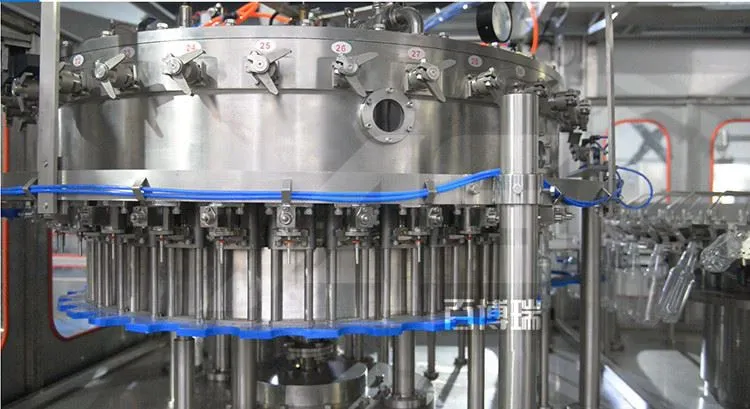

The configuration of filler is advanced, pithy and rational and the driving and up-down transmission is located between the stainless steel working plat and the bracket and their waterproof is good, sanitary and credible and adjusting and maintaining are very easy.

-

The filling operation is faster and more stable because the new type micro pressure filling system is adopted.

-

The electropneumatic filling valves are equipped with interchangeable level tubes to make the best precision filling, and the filling level for the bottle is adjust.

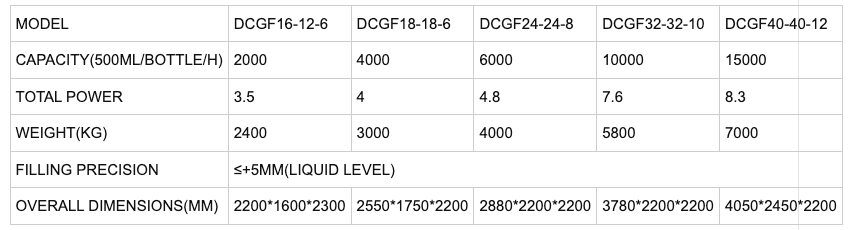

Parameter

Wash Heads

-

All 304/316 stainless steel rinse heads, water spray style inject design to save water consumption and much more clean.

-

304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

-

304/316 stainless steel washing pump

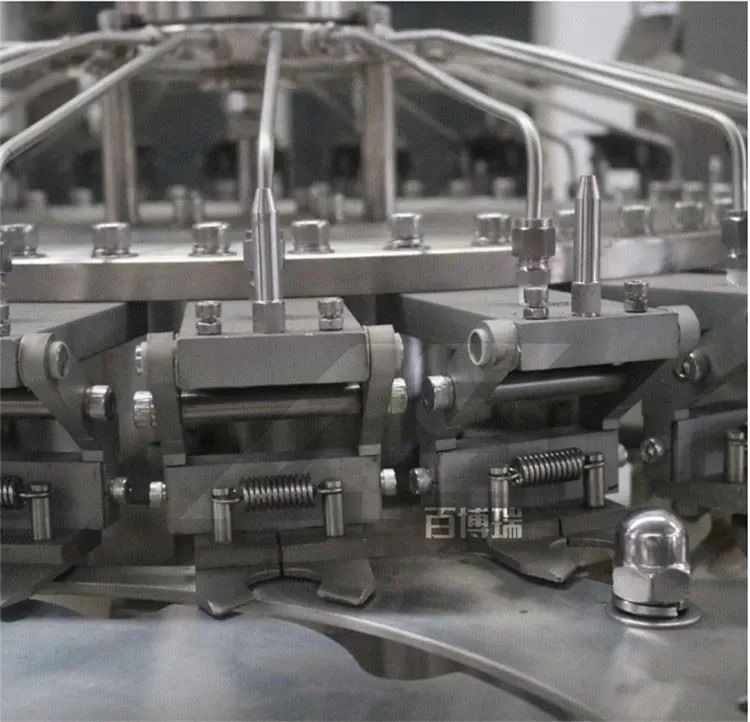

Filling Heads

-

304/316 Stainless steel high precision filling nozzle

-

Filling volume adjustable in fine rank, same liquid level after filling

-

All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

-

304/316 stainless steel filling pump

Capping Heads

-

Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

-

All 304/316 stainless steel construction

-

No bottle no capping

-

Automatic stop when lack of bottle

Our Company

Asiastar Beverage Machinery Co., LTD is a manufacturer specializing in the production and sale of liquid filling production equipment. The company has complete processing equipment, perfect technological process, strong technical force, excellent product development and design ability, rich production experience, etc. The company provides various services for the design, manufacture, installation, maintenance, technical improvement support, technical consultants, and filling production equipment for drinking water, pharmaceutical, and chemical manufacturers. The company specializes in the manufacture of liquid filling equipment for disposable barrels particularly. We have rich experience, reliable quality and good effect in equipment manufacturing and engineering construction. With the rapid development of science and technology, we adhere to the principle of precision manufacturing and perfection first in terms of functional design, material selection, welding technology, process quality control and even appearance beautification. Each process has been carefully planned and required and the products are sufficient to meet the hygienic inspection standards for the production of drinking water, medical preparations etc.

FAQ

Q1:What are you main products?

A:Asiastar Beverage Machinery Co., Ltd. is a 12-year-old manufacturer specializing in the production of beverage filling machinery and equipment. We have been certificated by the famous cercification authority. The products include: beverage filling machiner,hot filling production line, Pure water filling machine, pure water production equipment, oil filling machine; beer can(bottle) filling machine;milk filling production line, 5 gallon filling production line , carbonated soft drink production line , big bottle water filling production line , three-in-one filling machine, beverage equipment, etc. Similiar equipments contain water treatment plant ,PET bottle blowing machine,bottle unscramber machine,labeling machine,packing machine,sterilizer,date printer,etc. We can help you to start a new company in beverage production line .we make all of our customers be satisfied with the machine and our service.Any question about this machine or our factory , please contact us ,sincerely serve for you .

Q2:How can I install my machine when it arrives?

A:We will send the engineers to install and test the machines and have training lessons abroad, but the Visa fee, round tickets, accommodation, eating, and the allowance of 80USD per day per person will be on customer's side.Or the customer can send the engineer to our company to complete the inspection of the goods, as well as the installation and training lessons ,but the Visa fee, round tickets, accommodation, eating, and the allowance will be paid by customers .

Q3:What's your guarantee or the warranty of the quality if we buy your machines?

A:We offer you high quality machines with 1 years guarantee . we will give u free spare parts in 2 years. If during the warranty period, the quality or specification of the goods is found to be inconsistent with the contractual requirements, or if the goods are found to be defective (including potential defects or the use of unqualified materials, etc.), the buyer has the right to use the inspection documents issued by the statutory authority. During the warranty period of the goods, the buyer shall make a claim against the seller.

Q4:How can l get some samples?

A:We have no sample.we will send you more pictures and video about this machine,and welcome to visit our factory to see the machine running in the factory.

Q5:How about the quality of your products.

A:Our company guarantees that the products provided are brand new, unused, with the latest design and suitable materials, and comply with the quality, specification and performance of the contract in all respects.

Q6:What's the delivery time?

A:7-45 days after the T/T deposit or L/C.(The premise is to receive customer's samples and deposit).