Product

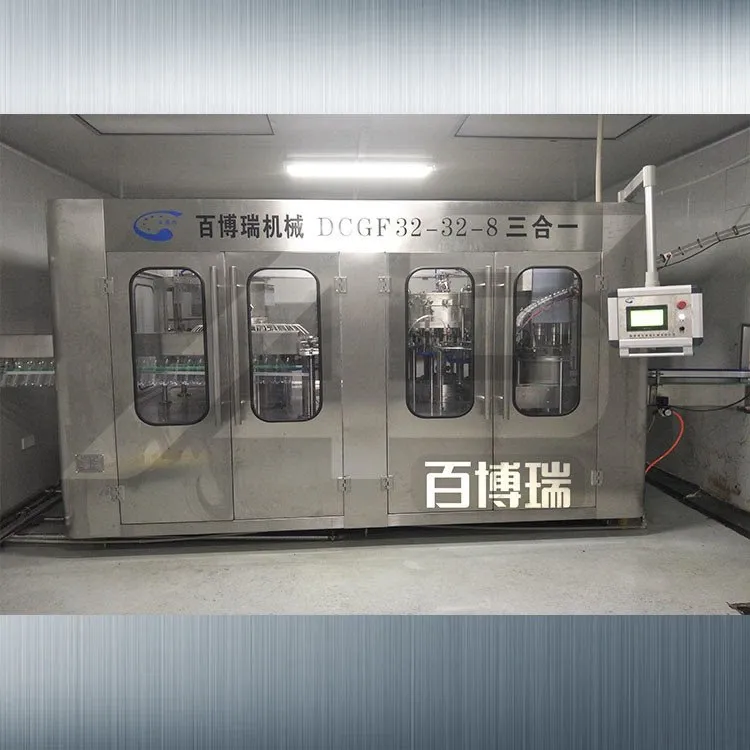

Automatic Carbonated Filling And Capping Machine

Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

Product Features

Product Description

Beverage Machinery-Equipment characteristics

-

Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

-

Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough.

-

The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

-

The cylinder drive the valve the movements is accurate and reliable. High-throughput, high-precision filling valve, filling fast and accurate. Equipped the CIP loop and control procedures, the equipment is easy to clean.

-

Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

-

Using the programmable controller as control centers; using pressure transmitter, electromagnetic measurement to maintain the balance of liquid surface so as to ensure the stability of liquid.

-

New designing filling valve, return gas and filling liquid are separate to ensure the filling materials is clean.

-

The machine adopt advanced magnetic clutch screw lid and the torsion torque is adjustable, so screwing is safe and reliable.

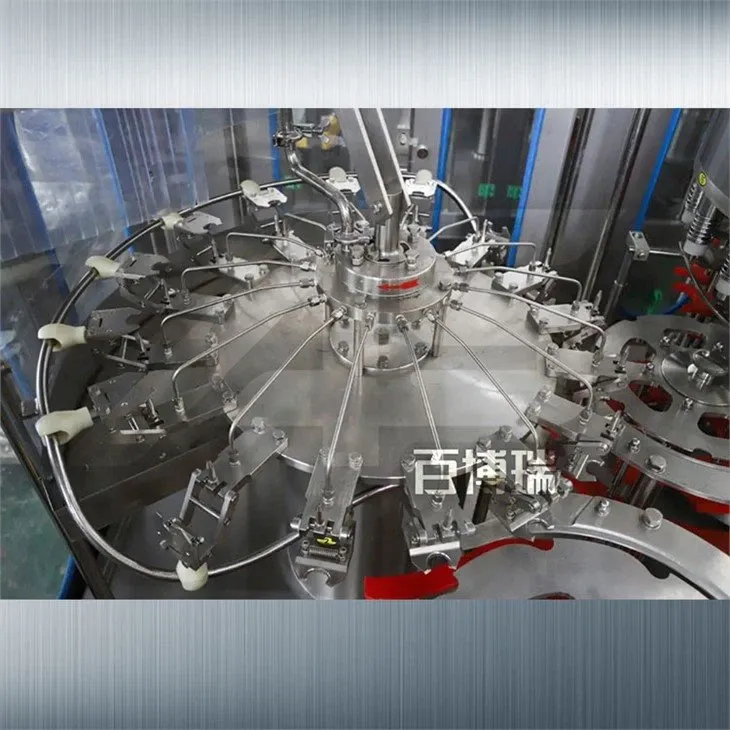

Washing Heads

1.Into bottle way is air conveyor direct connection with Bottle dial

2.All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

3.304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

4.304/316 stainless steel washing pump make the machine more durable

Filling Heads

1.304/316 Stainless steel high precision filling nozzle

2.Filling volume adjustable in fine rank, same liquid level after filling

3.All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4.304/316 stainless steel filling pump

5.Efficient spray nozzle rinse thoroughly and save water for flushing

Capping Heads

1.Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping 2. All 304/316 stainless steel construction 3. No bottle no capping 4. Automatic stop when lack of bottle 5.Capping effect is stable and reliable ,Defective rate ?0.2%

Company Profile

Certificates

Payment And Delivery

- Payment Term:

- 30% T/T in advance as deposit , and the balance be cleared before shipment ;

- Sample Provide

? The customer should supply no less than 50pcs samples for each kind of bottle and 200 pieces samples for each kind of cap within a week after the contract is signed

? If customer without bottle sample yet, need provide the bottle & capper drawing with full dimension details

- Delivery & Packing

-

Delivery Time: 30 days after get the bottle & Caps sample or get the bottle & cap dimension

-

Coming Document:

? Machine Quality Guarantee

? Complete set install & maintain instruction Book in English language

? Complete Document for customer clearance

- Packaging requirement

? The special packaging box is according to the immunity standard in China?it suits for long-distance transport, damp proof, rustproof, land way and seaway.

? Transportation ways: Ocean transportation

- Install in Spot

- If our Engineers install in spot

? Installment USD80/day. Person as allowance

? Training fee is free for customer’s workers within the installation period

? The tickets from China to the customer factory and return paid by the customer

? The visa cost, local housing , food, and transfer cost at customer factory paid by the customer

- Mechanical Warranty

-

Offer 12 months maintenance period to the problem that caused by our design, manufacture and the material quality, and offer the relevant parts and effective service for free for above reason.

-

Come with one year’s recommended spare parts

FAQ

Q1: Are you a trading company or a manufacturer?

A: We have our own factory for many years,can give u best service.

Q2: What's your guarantee if we buy your machines?

A: We offer you high quality machines with 1 year guarantee and free spare parts for 1 year.

Q3: When can I get my machine after I paid?

A: We will deliver the machines on time as the date we agreed both side.

Q4: How can I install my machine when it arrives?

A: Our engineer will go to your side as soon as you get your machines ready for testing and teaching your technicians how to run the machines.

Q5: What's the delivery time?

A: 30-45 days after the T/T deposit or L/C.

Q6: Do you provide customized service?

A: We can design the machines according to your requirements (material, power, filling type, container and etc), at the same time we will give you professional suggestion by many years industrial experience.