Product

Automatic Soft Drink Filling Machine

This carbonated beverage filling equipment is made of SUS304/SUS316 material and adopts bottle neck holding transmission technology to realize fully automatic rinsing, filling and capping.

Product Features

Product Description

1.This carbonated beverage filling equipment is suitable for carbonated drinking, soft drinks, soda water, fruit containing gas beverage such as Coca Cola, Sprite, Fanta,etc. The machine also applies to drinks without gas,such as mineral water, pure water, etc.

-

This carbonated beverage filling equipment is made of SUS304/SUS316 material and adopts bottle neck holding transmission technology to realize fully automatic rinsing, filling and capping.

-

It is equipped with CO2 accuracy pressure control,so that the liquid level is always stable.

4.The application of alarm devices for bottle jam,bottle shortage,bottle damage,cap shortage,over loading etc,in several places ensure the quality of its production.

5.The machine obtains advantages of high reliability, high efficiency, high grade of automation and easy operation,etc.

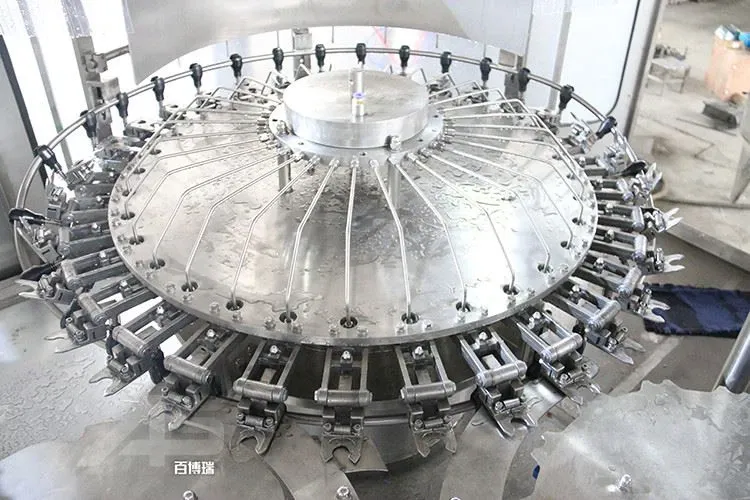

Washing Part

This machine adopts rotary structure and the rotating discs are welded with stainless steel SUS304. The PET bottle enters the equipment by means of the separating star wheel. The neck of the bottle is clamped by a clamp and a turnover mechanism and transferred to the bottle neck facing downwards. The sterile water is washed thoroughly and then drained.The bottle washer is equipped with a water tray to recover the bottle water.

Filling Part

The rotary disc is made of stainless SUS304 with large flat toothed bearings, smooth and reliable operation.The machine adopts isobaric filling method with high precision and high speed liquid level filling valve. The machine uses ring cylinder and the liquid level is controlled by magnetic float level gauge. The equipment adopts bottle neck holding and pre-cover to clamp the bottle neck so that it is convenient to change the bottle shape without changing or adjusting any parts.

Capping Part

The capping and capping technology imported from Italy is at the domestic leading level. It adopts international advanced processing and manufacturing technology. The use of constant torque capping machine is different from the previous magnetic disc capping head. More stable and accurate screw cap twisting torque, more reliable screw cap effect, can better reduce the defective rate of capping and the loss rate.

Equipped with a capping machine bottle feed detection switch, and a lock cylinder at the connection of the capping guide rail and the dial interlocks to control the discharge of the bottle cap, ensuring that the cap feeding is stopped when there is no bottle, reducing the loss of the user's cap.

A set of photoelectric switches are installed on the cap-dropping rail. When there is no cap on the cap-dropping rail, it will automatically stop the machine and alarm, which can effectively avoid the appearance of bottle without cap.

Related Products

- Water treatment system

- Carbonated drink prepare system

- Sugar filter/ Sugar melting tank

- Sugar cooling system/Double head filter

- Blending tank

- Freezer equipment

- Carbonated drink mixing machine

- PET bottle blowing machine

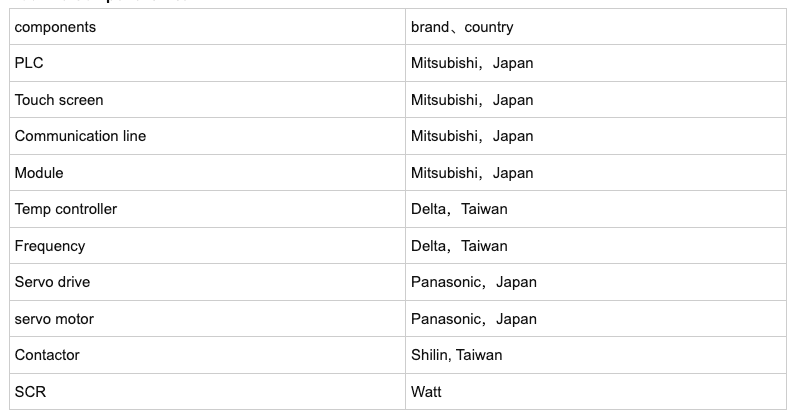

Machine Component List

Packing Machines

- Bottle warmer/Bottle cooler

This machine is a new design of similar equipment technology at home and abroad. It adopts the multi-stage treatment of heat preservation and gradual temperature rise. Through the three-stage spray system, hot water is used as the heating medium to heat up the filled products quickly and evenly, so as to ensure the quality of products. And quickly rise to normal temperature. The insulation section of the equipment uses 50 ? hot water to keep the material warm for 10min; the second section uses tap water circulation cooling, and the third section uses pure water to wash the bottle body to prevent the bottle body from stains. The box body of the equipment adopts the split combination structure. The system adopts the continuous heating mode of circulating water. The main drive reducer motor adopts frequency control and PLC program controller control. The spray head is made of nylon material, and the spray of each nozzle is even. The warm water collecting tank is equipped with high and bottom liquid level alarm devices.

- Sleeve label machine

Sleeve the labels into the bottles, and then with the conveying belt the bottles will pass through the steam tunnel, the labels will be shrinked.

- Laser code machine

Function:With the laser technology, crave producing date , expiry date , and other information in the bottles requried

- Heat Shrink film packing machine

Function: Film wrapping the bottles, and easy for transporting