Product

PET Bottle Carbonated Drink Filling Machine

This monobloc machine is quite easy to be operated and maintained with the adopting of SIEMENS PLC control of frequency conversion Timing.

Product Features

Product Description

This monobloc machine is quite easy to be operated and maintained with the adopting of SIEMENS PLC control of frequency conversion Timing.

All the parts contact with liquid are made up of high quality stainless steel 304 , both exterior and interior of the machine are polished for easily cleaning and good hygiene codition.The sealing parts are all imported from foreign countries, which meets the requirement of the hygiene of the foodsafety.

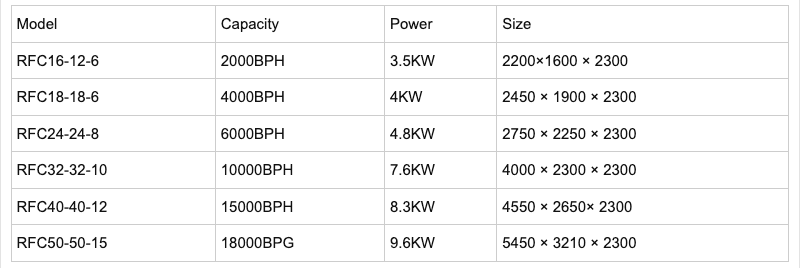

Technical Parameter

Washing Part

Rotatory bottle-rinsing machine has the functions of not opening the valve and rinsing without bottle, which is working from bottle entrance, bottle transportation, bottle clipping, bottle turning around with synchronously rinsing inside of the bottle to water-dropping and exit have the functions of not opening the valve and rinsing without bottles.

Filling Part

-

The rotate plate is made of stainless steel 304, large flat toothed bearing.

-

The pressure mechanical valve is introduced the advanced foreign design with a fast filling speed, no hygiene corner pocket, a few sealing parts, and precise liquid level control. The whole valve is made of food grade stainless steel.

-

The beverage supply adopts the automatic pneumatic valve magnetic liquid-level switch to control the liquid tank automatically.

-

The motivation of the filler is derived from the driven system in the framework and passed by gear.

-

The main drive adopts gear drive, with high efficiency, low noise, long life, easy maintenance, sufficient lubrication, grease can lubricate centralizing automatically, adopts transducer to the speed of main motor to control, the machine adopts step-less frequency conversion timing. The material for the whole platform and frame is carbon steel with stainless steel outside.

-

The machine is automatically controlled by PLC, fault on line display, like bottle block, cap shortage etc.

Capping Part

Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

No bottle no capping

Automatic stop when lack of bottle

Capping effect is stable and reliable, Defective rate ?0.2%

Our Company

ASIASTAR as one of the major beverage machine manufacturer in China , was established in 2000. With more than 10 years producing and exporting experience , we can offer compleAte solution to design ,manufacture ,pack, transport , install , maintain the beverage packing machines according to out cutomer's requirement.

FAQ

Q1:Are you manufacturer or trading company ?

A: We are industrial manufacturer, which locates in Xinyi city over 10years , and begin to export our machines and provides oversea installation services since 2009 .

Q2:How can we get your suitable machines / production line?

A: 1. Let me know what kind of products will you produce ?

-

Let me knw what is the capacity(per hour) you want ?

-

Let me know what kind of package , plastic bottle ,glass bottle : volume ,height ,neck diameter ,diameter of bottle or other please inform us of details

Q3: Do you have any technical supports with your Beverage Filling Machines?

A: Yes, We have a professional team of engineers who owned many installation, debug and training experiences abroad, are available to service machinery overseas.

Q4: What kind certificates you already passed ?

A: We already passed CE , SGS , CIQ , ISO etc.