Product

10L Bottled Water Filling Machine

RFC series, after years of updating, repeatedly absorbing customer feedback information and learning from foreign advanced technology,

Product Features

Product Description

Machine Introduction

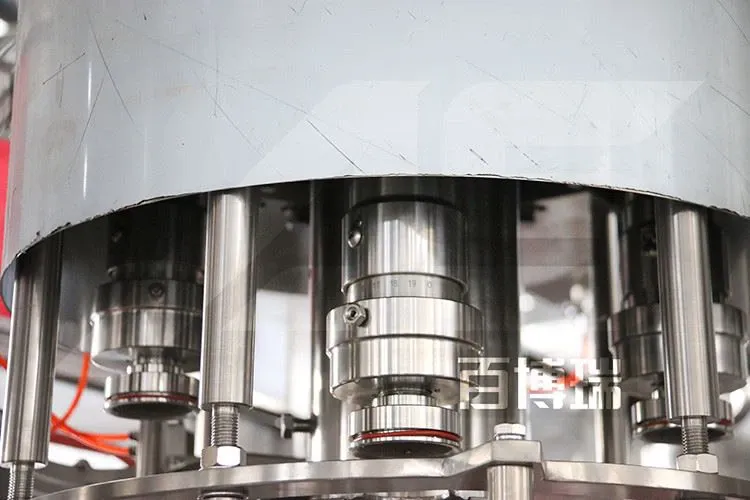

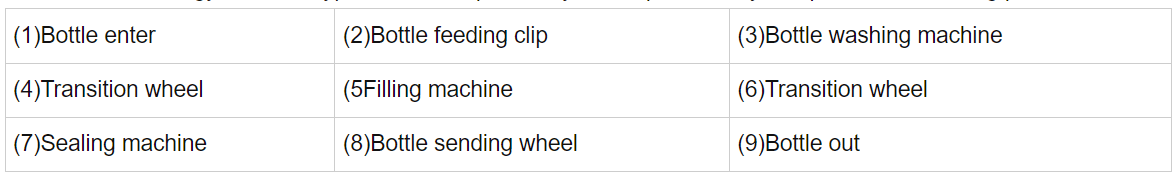

RFC series, after years of updating, repeatedly absorbing customer feedback information and learning from foreign advanced technology, is a new type of unit independently developed, mainly composed of 9 working parts:

Rinsing Part

-

All 304/316stainless steel rinse heads, water spray style inject design, more water consumption saved and cleaner.

-

304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

-

304/316 stainless steel washing pump

Filling Part

-

304/316 Stainless steel high precision filling nozzle

-

Filling volume adjustable in fine rank, same liquid level after filling

-

All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

-

304/316 stainless steel filling pump

Capping Part

-

Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

-

All 304/316 stainless steel construction

-

No bottle no capping

-

Automatic stop when lack of bottle

Related Products

The reverse osmosis device is an equipment to purify the saltine water with the action of pressure difference of semi permeable membrane. It is called reverse osmosis, as it is counter to natural penetration direction. Different materials have different osmotic pressures. The reverse osmosis method to adopt larger osmotic pressures is used to obtain the purpose to separate, extract, purify and condense.

More than 97% soluble salts and 99%glues, microbe, particulate and organic substances and etc can be removed with the reverse osmosis. It becomes the most idea equipment for the modem program of pure water, hyper pure water, and airspace water. The remarkable characteristics of the equipment are shown as lower energy consumption, no pollution, simple techniques, high water quality, easy operation and maintenance.

Bottle Blowing Machine

1). Stable performance with advanced PLC.

2). Automatic preform conveyer to save human cost.

3). Preform self-rotation and infrared pre-heater revolution assure the even distribution of heat, which improve the bottle shaping rate, increase the production.

4). High adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity invariable.

5). High safeties with security automatic-locking device in each mechanical action, which will make the production into a perfect safe environment, in case of the breakdown in certain procedure.

6). Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

7). Strong clamping force with high pressure and double crank links to lock the mould.

8). Two ways of operating: automatic and manual.

9). Low cost,high efficiency,easy operation and maintenance etc, profited from the fully automatic technological process.

10). Ideal cooling system make the finished bottles without any flaws.

Laser Code Machine

laser marking machine intergrated the best laser generator and scanner in china, which makes it marking in high speed with high-accuracy. We try to make laser marking machine more easy to use, so we also intergrate the computer and software. It can work with rotary attachment to marking pipes.

Heat Shrink Film Packing Machine

Automatic PE film heat shrink wrapping machine is suitable for wrapping of such products as poptop, mineral water , bottle beer and drinks etc. Without bottom tray ,it is working with PE film shrink tunnel to pack the goods perfectly , the whole production process adopts the German advanced technology, and the main parts are imported from international famous companies .It has stable capacity and can be used for a long time ,it consists of seven actuating motor , through cooperation with 7 actuating motor to form the product package with plastic film and several bottles as a group come out from the hot shrinking packing machine.