Product

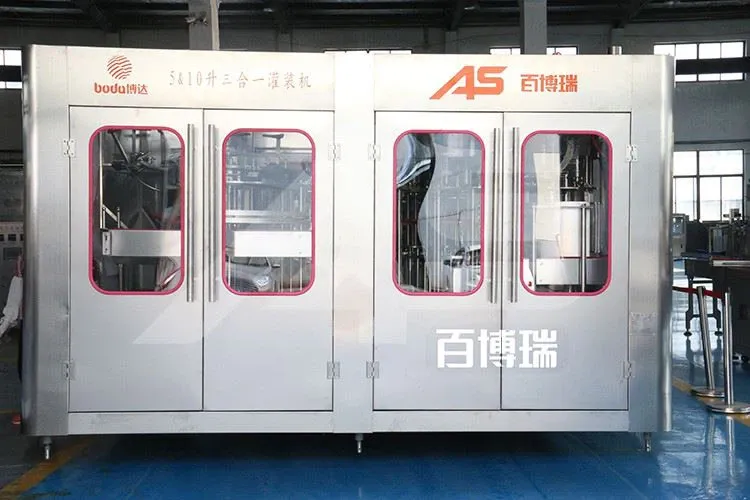

10L Water Bottle Filling Equipment

The bottle-necks are cramped and bottles are suspended during the operation process. This avoids many malfunctions caused by thinner bottle body or different highness of bottles.

Product Features

Product Description

-

The bottle-necks are cramped and bottles are suspended during the operation process. This avoids many malfunctions caused by thinner bottle body or different highness of bottles. This design also reduce dramatically the required number of changeable parts , make it more convenient and quickly to change to another type of bottles.

-

The most advanced technology from Japan and Germany is employed in the design.The gravity fixed liquid surface filling is used. The filling is fast, the amount of liquid is accurately controlled and the dropping and leakage are avoided.

-

Spring cramps are used in the bottle washing process. The empty bottles can be turned over 180* along the conveying rail. There are two times of internal and external washing, the efficiency of bottle washing is high.

-

The magnetic torque is used for screw capping. The power of screw capping can be adjusted without steps. The power of the screw capping can also be fixed,and the caps will not be damaged, the capping is reliable.

-

Horizon swirl air power caps sorting device is used to avoid damaging the surface of caps, and when there is a shortage of caps in the caps storage tank,an alarm signal will be generated and the caps will be fed automatically.

-

The whole machine is controlled by PLC .The amount of the drinks in the storage tank can be controlled automatically. The filling and capping will be stopped automatically when there is no bottle. When bottles are crapmed wrongly or when caps are not available, the machine can be stopped automatically.

-

The frequency changing technology is used to adjust the operation speed .

-

The frame is made of high quality stainless steel,covered by S.S.304,the filling valve parts direct contact with water are made in SUS304 stainless steel .

Washing Part

1.Stainless steel 304/316L washing heads.

2.Using unique design,avoid the traditional bottle on rubber clip to block the bottle threaded parts may be caused by the pollution.

3.Washing pump is made of stainless steel.

4.By high spray nozzle, blunt bottle of water jet angles, flush to the bottle of any part of the inner wall, rinse with water thoroughly and save flush bottle.

5.Bottle clamp and flip agencies sliding sleeve adopts Germany igus corrosion resistant bearing without maintenance.

Filling Part

1.Filling method for gravity filling.

2.Filling valve manufactured SUS 304/316L.

3.High precision, high speed liquid filling.

4.Filling move by the rack drive system through gear transmission.

5.Hydraulic cylinder controlled by a float liquid level.

6.Using the latest double guide pillar type bottle of lifting mechanism, avoid the bottle of elevating the old products must be through the mesa caused by leakage on the edge, at the same time, easy installation and maintenance.

Capping Part

1.Automatic check,no bottle no capping.

2.Capping heads in stainless steel 304/316L.

3.Capping heads stop working when lack of bottle.

4.Fall guy guide sets out to prevent the cover through and cover on the body, at the same time equipped with a set of photoelectric switch, automatic stop when lighted cover rail without cover machine, can effectively avoid the occurrence of open bottle.

5.High efficiency centrifugal principle.

FAQ

Q1:The after-sale service

A: 1. 12 months warranty to change the spare parts which are damaged by non-human factors for free. solve basic questions by telephone, email, whatsapp, wechat and video call.

- Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines. Operating manuals will be sent with machine or by email.

Q2:When can i get engineers from you?

A:When you finish the Preparation conditions(water resource,electricity,air supply,production materials)contact with our sales people we will dispatch engineer to install the machine for you ,and train your employees to use the machine well.Normally when you preparation is done,you contact with our sales people and cooperate us to get the visa for the engineer and our engineer will be there within 15 days.

Q3: Do you have reference project?

A: We have reference project in most countries,If we get the permission of the customer who has brought the machines from us ,you can go to vist their factory. And you are always welcome to come to visit our company,and see the machine running in our factory,we can pick you up from the station near our city. Our sales people you can get video of our reference running machine

Q4: What should I do if we are not able to operate the machine when we receive it?

A: Operation manual and video demonstration sent along with the machine to give instructions. Besides, we have professional after-sale group to customer 's site to solve any problems.

Q5:Where is your factory location? How can I visit there?

A:Our factory is located in Xuzhou City,China.You could visit us by air to Xuzhou Airport then we will pick you up to our factory.

Payment And Delivery

Payment Term

- 30% T/T in advance as deposit , and the balance be cleared before shipment ;

Sample Provide

- The customer should supply no less than 50pcs samples for each kind of cap and bottle within a week after the contract is signed

- If customer without bottle sample yet, need provide the bottle & capper drawing with full dimension details

Delivery & Packing

- Delivery Time: 30 days after get the bottle & Caps sample or get the bottle & cap dimension

Coming Document:

- Machine Quality Guarantee

- Complete set install & maintain instruction Book in English language

- Complete Document for customer clearance

Packaging requirement:

- The special packaging box is according to the immunity standard in China?it suits for long-distance transport, damp proof, rustproof, land way and seaway.

- Transportation ways: Ocean transportation

Install in Spot

- If our Engineers install in spot

- Installment USD80/day. Person as allowance

- Training fee is free for customer’s workers within the installation period

- The tickets from China to the customer factory and return paid by the customer

- The visa cost, local housing , food, and transfer cost at customer factory paid by the customer

Mechanical Warranty

- Offer 12 months maintenance period to the problem that caused by our design, manufacture and the material quality, and offer the relevant parts and effective service for free for above reason.

- Come with one year’s recommended spare parts