Product

12L Mineral Water Bottle Filling Machine

The suspending bottle-neck cramping design assures whole production line more stable during the working process and it also avoids malfunctions caused by the different bottle thickness or height.

Product Features

Product Description

-

The suspending bottle-neck cramping design assures whole production line more stable during the working process and it also avoids malfunctions caused by the different bottle thickness or height. The design also dramatically reduces the required quantities of interchange parts which make it more convenient to change different types of bottles on washing, filling and capping.

-

Advanced gravity filling technology from Germany and Italy is applied on the machine, which assure quick filling and high accuracy of liquid level control.

-

Magnetic torque is applied on bottle screw-capping. Constant screw capping power can be adjustable stepless and therefore will not hurt the bottles at all.

-

Horizontal swirl cap sorting device is applied to avoid damaging caps. No caps, no capping; No caps, feeding system run automatically.

-

Human-machine interface touch-screen and PLC control system are adopted on the machine. Liquid level in the tank is controlled automatically. No bottles, no filling, no capping.

-

All parts connected with water are made of food grade stainless steel.

-

All main components makers are world-known manufacturers

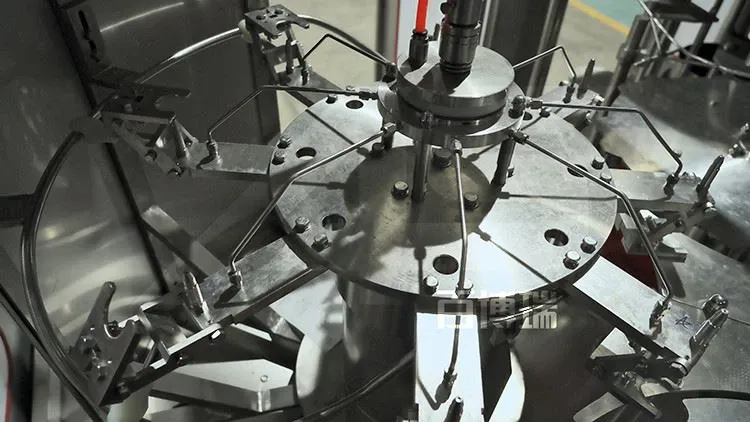

Rinsing Part

The rotary wheel is a fully SUS304 stainless steel welded structure.

The machine applies unique overturning bottle clamp, which is an innovation of our company. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp. Made of SUS304 stainless steel, this bottle clamp is hygienic and durable.

The high efficiency atomizing spay nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and also saves rinsing water.

All sliding bushes of lifting device use Igus (Germany) anti-corrosion maintenance free bearing.

The rinser is driven by driving system positioned inside machine frame via gear transmission.

Transfer Starwheel

Made of stainless steel of superior quality.

Equipped with bottle jam protection device.

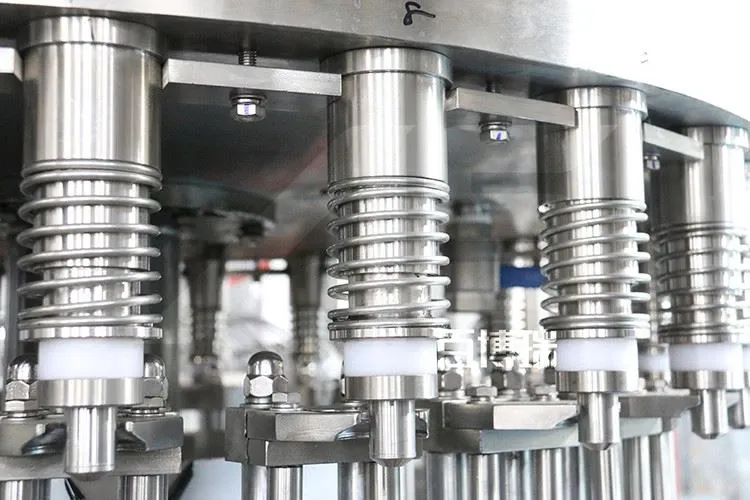

Filling Part

The blow-made bottles are transported to filler via starwheel. After entering filler, the bottle is held by gripper of lifting cylinder and realizes up and down under effect of cam.

The filler adopts gravity filling way. Bottle mouth rises to open filling valves and start filling. While product rises and plugs up air return hole, the filling will be finished. After filling, bottle mouth moves down and leaves the filling valve.

Capping Part

Capper is the highest precision machine,it influences the stability and reliablity of the filling monoblock very much.Our capper features as follows:

Cap distributing chute is equipped with reverse cap stop and reverse cap pick-out mechanism.

Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute.

The capper is equipped with inlet bottle detection switch.

Centrifugal way of cap arranging is adopted to reduce damage of caps.

A cap inspecting system is applied to control on-off of elevator.

Our Company

Xinyi Asiastar Beverage Machinery Co.,Ltd. as one of the major beverage machine manufacturer in China, was established in 2009. We are professional in producing various kinds of rinsing filling capping machines and other packing machines both for liquid and semi-liquid.

Certifications

FAQ

Q1:Can you customize for clients?

A:Yes, we can customize as your need, we have R&D department, our designers can make design for you and our technicians make prototype.

Q2:How far is your factory from the airport?

A:From airport about 40 minutes by taking the high speed rail, We can pick up you.

Q3:Do you have after-sale service?

A:Yes, Good after-sale service, handling the customer complaint and solve problem for customers.

Q4:Can you arrange shipment for customer?

A:Yes, very good experience in shipping, we work with the most reliable shipping companies in the world.