Product

3-20L Liquid Filling Machinery

The suspending bottle-neck damping design make the bottle stable during the high-speed moving conditions ,by changing a few parts it can meet the production of different types of bottles easily.

Product Features

Product Description

1.The suspending bottle-neck damping design make the bottle stable during the high-speed moving conditions ,by changing a few parts it can meet the production of different types of bottles easily. the new generation of SS grabis adopted and the grabs have no contact ,with the area above the bottle's screw thread nozzles in the grad it can guarantee the complete wash of the interior of the bottle.

2.The advanced graving filling technology used in this machine makes the filling quick ,steady and accurate.

3.Magnetic torque is used for screw capping and the power of screw capping can be adjusted step-less, capping is reliable and do no harm to the caps

4.Advanced technologies such as human-machine inter face touch-screen and PLC program control are adopted in this machine

- All parts that have direct contact with the water are made of high quality SS ,the critical electrical components are from famous international companies such as Mitsubishi ,Omron to the name a few.

Rinsing Part

-

Into bottle way is air conveyor direct connection with Bottle dial .

-

All 304 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean .

-

The gripper equipped with high-efficient spray nozzle, it can develop to any position of inwall of the bottle, and can save rinsing water.

-

Rinsing time can be guaranteed for 4 seconds.

-

The supplying of rinsing water is controlled by solenoid valve.

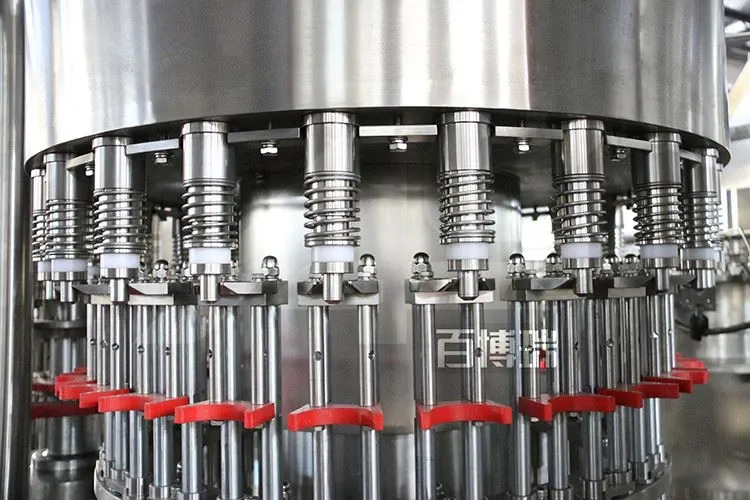

Filling Heads

-

The three-in-one unit completes the three processes of bottle washing, filling and capping at one time, with little bottle wear, accurate and stable transmission, and convenient bottle type replacement.

-

The specially designed all-stainless steel bottle washer bottle clamp is sturdy and durable, and does not touch the threaded part of the bottle mouth to avoid secondary pollution of the bottle mouth.

-

High-speed and large-flow gravity filling valve, fast filling speed, accurate liquid level without liquid loss.

Capping Part

Bottles enter capper via transition starwheel. The anti-rotation knife of capper blocks bottle neck to keep bottle vertical and prevent rotation. Capping heads keep revolution and do rotation. Under effect of cam, the action of gripping cap, sleeve cap, screwing cap and discharging cap to finish the whole capping course. The finished bottles are conveyed via bottle-out starwheel onto bottle-out conveyor, and then are sent out of the combiblock. The whole machine adopts console sealing windows, beautiful and decent.

Sleeve Labeling Machine

Certification