Product

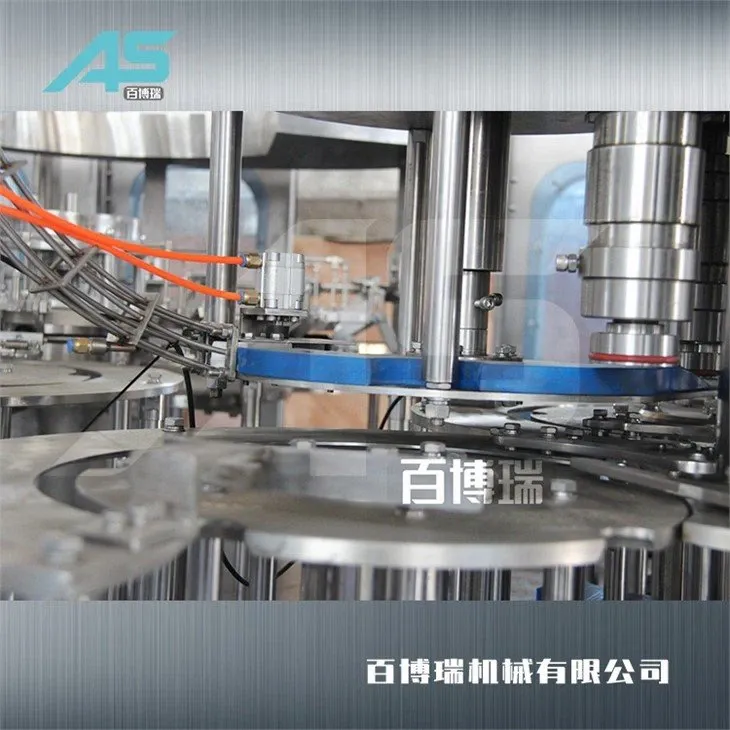

5L Automatic Bottled Water Filling Machine

The three functions of bottle washing, filling and capping are composed in one body of the machine is used to fill mineral water and purified water in bottles made of polyester and plastics.

Product Features

Product Description

The machine mainly used in the beverage filling operation. The three functions of bottle washing, filling and capping are composed in one body of the machine is used to fill mineral water and purified water in bottles made of polyester and plastics. The machine is conveniently turned to adjust the machine to fill various types of bottles. The filling operation is faster and more stable due to the micro-negative pressure filling operation of the new type is adopted. The output and benefit of the machine is higher than the machines of the new type is adopted. The output and benefit of the machine is higher than the machines of the same specifications. The advanced OMRON programmed controller(PLC) is adapted to control the machine runs automatically, air conveyor system is adopted in bottle entry section and belt conveyor system is adopted in bottle Exit section, which can adjust speed and coordinated with transducer of the main machine to make the output of moving bottle forward steadily and reliably. It is convenient to operate with higher automation due to every parts of the machine is inspected to run with photo electrical detector. The machine is ideal-preferred equipment for beverage makers.

Washing Part

-

360 degree cleaning inside and outside of the bottle,no dead Angle.

-

All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean .

-

The flushing pressure can be adjusted.

-

304/316 stainless steel pump.

Filling Heads

-

304/316 Stainless steel high precision filling nozzle.

-

Filling volume adjustable in fine rank,same liquid level after filling.

-

All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean.

-

304/316 stainless steel filling pump.

Capping Heads

-

With putting capping system and electromagnetic capping heads.

-

All 304/316 stainless steel construction.

-

No bottle no capping. automatic stop when lack of bottle.

FAQ

Q1: This is the first time I cooperate with your factory. How can I trust you about the machine quality?

A: Before ordering the machine, we will make the offer very clear. For example, the material thickness the brand etc. We can have the video call and I will show what we have in the factory; Also you can visit us to see the machine

Q2: If the quality doesn't meet my requirement, how can you solve this problem?

A: Before ordering the machine, we will negotiate the machine inspection standard. Then start production; If you are not satisfied with the quality, show us, we will re-do it before shipping;

Q3: How can I install the machine and commissioning? Do you have the technician to my factory?

A: We have the technician available to your factory for machine installation and commissioning; But client should be responsible for the round-way flight tickets, technicians' daily salary, local transportation local hotel and eating.

Q4: What is your warranty for the machine?

A: The valid time for the warranty of our machine is one year; we will provide the spare parts to the buyer total for free in one year, which do not include those damaged or broken parts caused by human. And the vulnerable and consumptive spare parts are also out of the range of guarantee.Buyer needs to pay for the shipping or air charges.