Product

15000BPH Juice Filling Machine

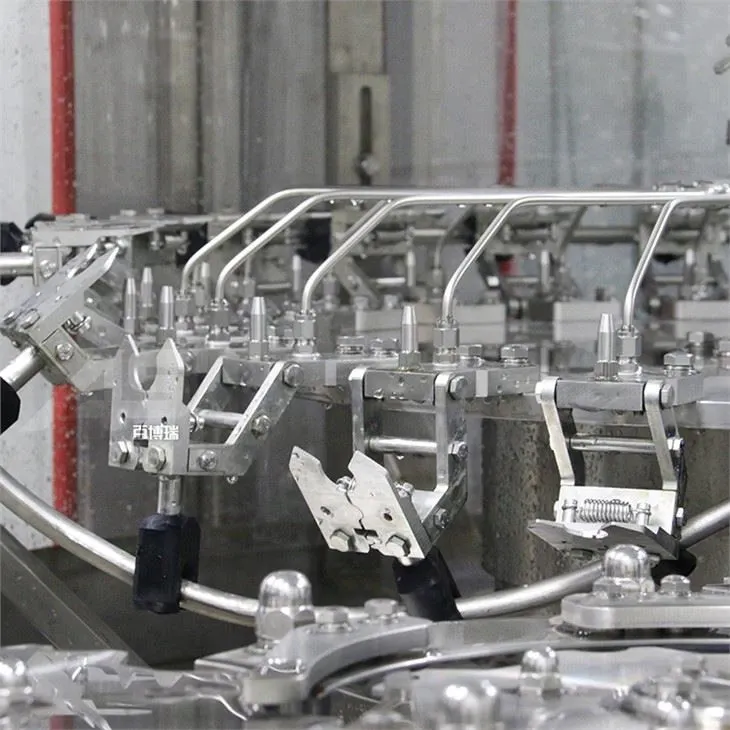

The filling line is mainly used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine.

Product Features

Product Description

1.The filling line is mainly used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic.

2.The filling operation is faster and more stable because the micro pressure filling operation of the new type is adopted. There the output and benefit of the machine is higher than the machinery of the same specifications.

3.The machine is used for filling juices and beverage in bottles,which are made by polyester and plastics. The machine can also be used in hot filling if being installed with temperature controlling device. The handle of the machine can be freely and conveniently turned to adjust the machine to fill various types of bottles.

4.It is convenient to operate with higher automation because every part of the machine is inspected to run with photo electricity, On the bases, the filling parts of the machine can be changed into filling methods of lower vacuum.

5.The advanced OMRON programmed controller (PLC) is adopted to control the machine to run automatically while a transducer is used in the bottle -entering chains to adjust speeds and coordinated with the transducer of the main machine to make the operations of moving bottle forward steadily and reliably.

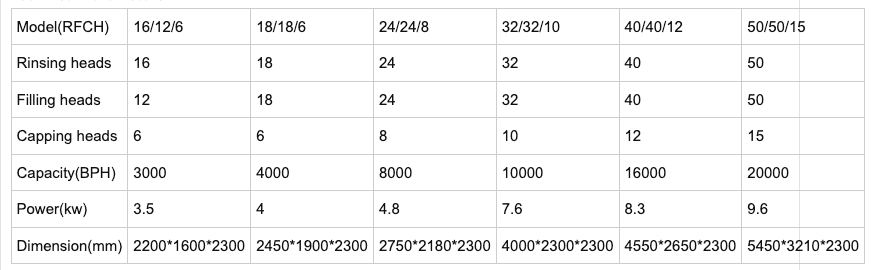

Technical Parameters

Washing Heads

Filling Heads

-

304/316 Stainless steel high precision filling nozzle

-

Filling volume adjustable in fine rank, same liquid level after filling

-

All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

-

304/316 stainless steel filling pump

Capping Heads

-

Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

-

All 304/316 stainless steel construction

-

No bottle no capping

-

Automatic stop when lack of bottle

Our Company

Asiastar Beverage Machinery CO.,Ltd is a professional manufacturer of Food and Beverage production line equipments,which integrate design and manufacture,installation and debugging,manning guide,after-sales service.

Based on the technical achievement and producing experience,we learn and digest the advantages of domestic and foreign friends,introduce the newest beverage packaging machinery technology from Germany and Italy to form our own competitive advantage.

Our equipment products are applied to multiple beverage fields such as carbonated beverage,fruit juice,pure water,spring water, sparkling wine.We can offer the whole water treatment system and automatic barreled water production line.The range of equipment we can produce covers the whole production line from pretreatment to filling and packaging system.Meanwhile,to fit some custom-made request for their different production conditions and capacity requirements,our engineers can also design special beverage machines.

The beverage filling machine of us not only sold throughout our China mainland, but also export to South Africa, Malaysia, Singapore, Burma, Sri Lanka and other dozens of counties.We have created a proud achievement in these years ,received widely by customers and laid a solid position in this beverage machinery field.

The company integrates the enterprise and the factory in one body.Production is connected with sales intelligently to fully guarantee the vital interests of the vast number of customers.

Our Company Service

- Payment &delivery

-

Before pay deposit Quotation send--order confirm --Proforma Invoice and contract for your esteemed company

-

Quotation send--order confirm --Proforma Invoice and contract for your esteemed company Pay 30% as deposit by T/T -Check the bottle mould --Send the preform sample----Machine will work first in our company and using your preform sample

-

After pay deposit Take some videos about machine running and working or your esteemed company come our factory check --the balance 70% payment will be cleared before shipment-- After machine arrive in your company , our engineer will installation in your company untill machine can work successfully and stably.

- Packaging requirement

a. The special packaging box is according to the immunity standard in China?it suits for long-distance transport, damp proof, rustproof, land way and seaway.

b. Transportation ways: Ocean transportation

- Installment

a. Installment USD80/day. Person as allowance

b. Training fee is free for customer's workers within the installation period

c. The tickets from China to the customer factory and return paid by the customer

d. The visa cost, local housing , food, and transfer cost at customer factory paid by the customer

- Machine Warranty

a.Offer 12 months maintenance period to the problem that caused by our design, manufacture, and the material quality, and offer the relevant parts and effective service for free for above reason.

b.Come with one year's recommended spare parts