Product

3000BPH Automatic Juice Filling Machine

The gripper in the rinsing machine will turn over the bottle with 180 degree, and then aseptic water will be Sprayed into the bottles , to finish the rinsing process.

Product Features

Product Description

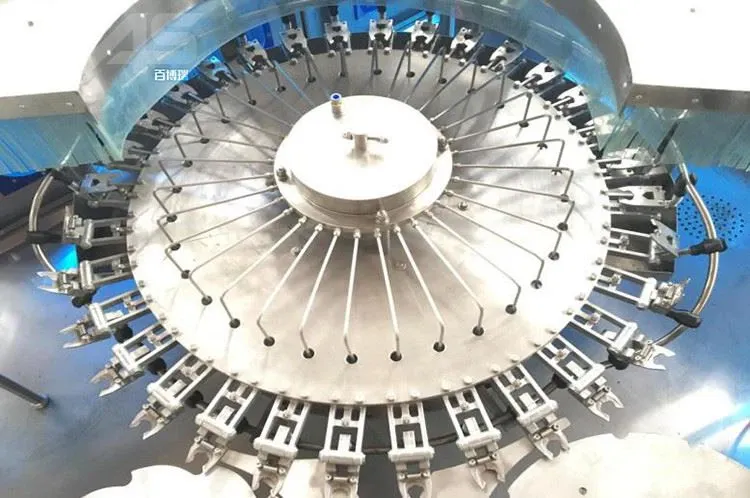

Rinsing Part

The gripper in the rinsing machine will turn over the bottle with 180 degree, and then aseptic water will be Sprayed into the bottles , to finish the rinsing process.

Filling Part

The gravity micro negative pressure filling method has high filling accuracy, stable filling, accurate control of filling liquid level, and can avoid material splashing to the greatest extent, which is conducive to keeping the bottle mouth and bottleneck clean and avoiding microorganism Pollution.

Capping Part

Our capping part have a set of photoelectric switch ,which is arranged on the cover rail, and when the cover rail is not covered, the machine can automatically stop running and alarm.

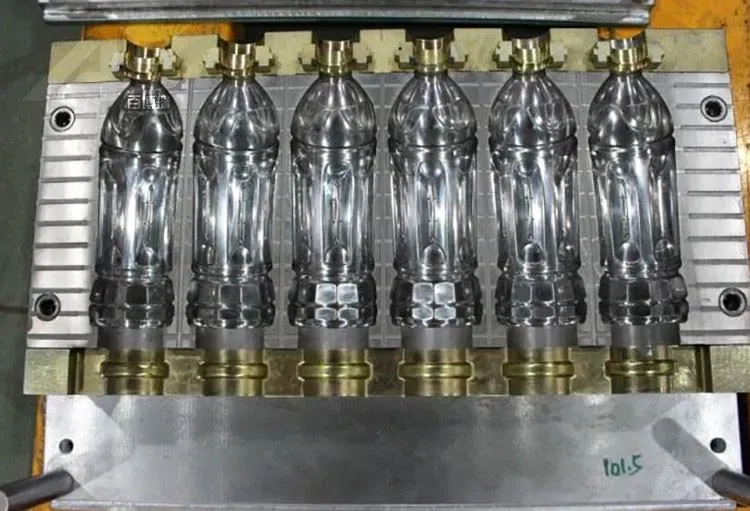

PET Bottle Blowing Machine

PET machines produce the widest range of packaging products available on the market.

We offers PET & PP bottling turnkey proposal

Our services range from pre-sale consultation to a complete plant setup including machinery and peripheral equipment planning. From perform design to blow molding, we offer complete service.

Applications

- Food

- Oil

- Carbonated drink

- Mineral water

- Juice

- Alcohol.

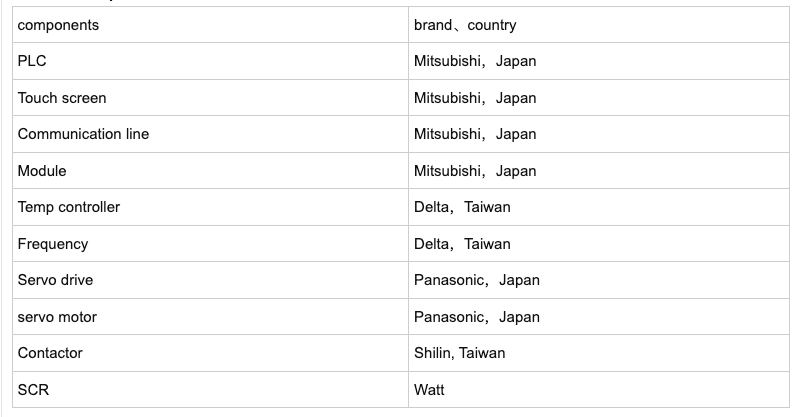

Machine Component List

Juice Prepare System

1.Sugar filter/Sugar melting tank

Sugar filter :The function of syrup filter is to filter the syrup out of the syrup melting tank. After filtering, the melted sugar becomes clear without any impurities.

Sugar melting tank:The machine has the function of high speed sugar, and can make the additives and materials, water mix evenly for the first time.

- Juice blending tank

This tank is for blending the water , syrup , and flavor, etc . It have the separate mouth for the water , syrup, they are used for online connection.

- Double head filter

All are made of SUS304 high-quality stainless steel, suitable for filtering all kinds of fine particles and impurities in liquid materials such as fresh milk, sugar liquid, beverage, glue liquid, Chinese herbal medicine liquid, etc.

- Juice Homogenizer

Juice beverage will be homogenized under high pressure, to prevent the juice delamination.

- Tube sterilizing machine

Using Principle high temperature sterilization to kill microorganisms and thermostable enzymes in products,After sterilizing ,the juice can be stored for a long time.

- Degasser

In the processing of fruit juice, the deoxidization of fruit juice is mainly carried out by vacuum method, even if the fruit juice is dispersed into film or mist point in vacuum state and deoxidized or other gases are removed; the vacuum degassing unit is applicable to all kinds of fruit juice drinks or other liquid foods in vacuum state; the fruit and vegetable juice drinks after degassing can reduce or avoid the composition of fruit juice Oxidation, reduce the change of color and flavor of fruit juice.

- High location tank

Storage the juice after sterilizing in high temperature,and it will be put up the juice filing machine as the picture show.

CIP Cleaning System

CIP is specially designed for the clean-up of beverage production line and filling equipment ?It includes alkali washing, acid pickling, high temperature pure water washing to ensure the cleanness of the pipeline for the next day's production.

Certification

Cooperated Brand

Company Information

ASIASTAR as one of the major beverage machine manufacturers in China , was established in 2000. With more than 10 years producing and exporting experience , we can offer complete solution to design ,manufacture ,pack, transport , install , maintain the beverage packing machines according to out cutomer's requirement.