Product

12000 BPH Bottled Water Filling Machine

Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough.

Product Features

Product Introduction

1.This machine Use the wind sent access and move wheel in the bottle directly connected technology;

2.Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough.

3.The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4.High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5.Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6.Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider.

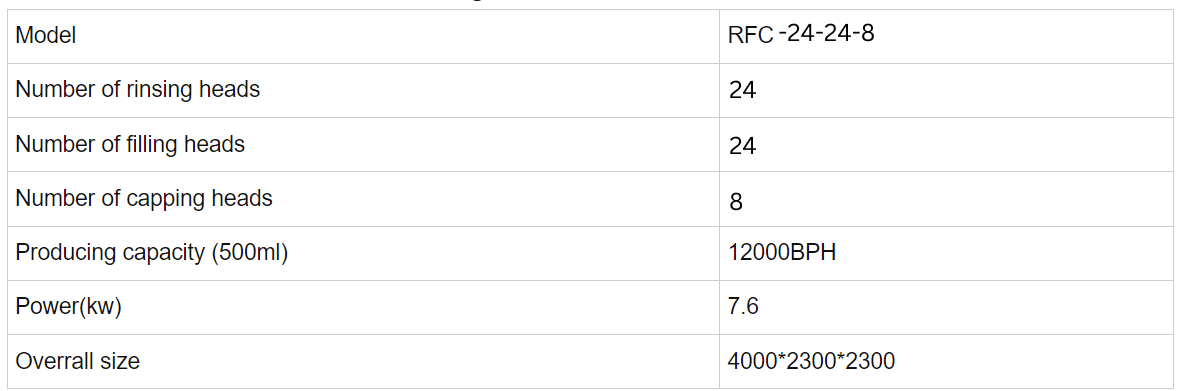

Technical Parameters (Bottled Water Filling Machine)

Washing Part

Spring cramps are used in the bottle washing process. The empty bottles can be turned over 180~ along the conveying rail. There are two times of internal and external washing, the efficiency of bottle washing is high.

Filling Part

Pure water mineral water bottling machine filling part:

Rotary wheel fully made of stainless steel SUS 304.

Gravity filling method.

Filling valves are made of SUS316L.

Filling valves are reasonably structured with accurate filling.

Filling flow can reach 200ml per second.

Bottles go up and down in the function of cam through elevator, to process filling with contact to bottle-mouth.

Level of cylinder is controlled with float-ball.

Filler is driven through gears inside the machine frame.

Link-wheels in rinser, filler and capper are transported in ringed support of bottle-neck

Capping Part

Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

All 304/316 stainless steel construction

No bottle no capping

Automatic stop when lack of bottle

Capping effect is stable and reliable, Defective rate ? 0.2%

Our Company

Asiastar :Our company is one of the major beverage machine manufacturers in China. We have more than 10 years’ experience in producing:

(1) 1-100MT/H water treatment system

(2) Water filling line

(3)Carbonated drink bottling filling line (beer, cola)

(4)Juice filling line

(5)Wine filling line

(6)Other packing production line includes label machine, ink jet code machine, heat shrink film packing machine, carbon box packing machine, etc. With our machines, bottles can be plastic bottle, glass bottle barrel and cans.different sizes bottle from 200ML to 20L can be filled.

FAQ

Q1: Which shipping way can you provide?

A: We can provide shipping by sea, by air and by express.

Q2: When can I get the quotation?

A: We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q3:What is your terms of delivery?

A:FOB, CIF, etc.

Q4:How can I place an order?

A:You can contact any of our sales person for an order. Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

Our Services

-

Training fee is free for customer's workers within the installation period.

-

Offer 12 months maintenance period ot the problem that caused by our design, manufacture, and the material quality, and offer the relevant parts and effective service for free for above reason.

-

Come with 1 year's recommended spare parts.

-

We provide the English instruction book for the machines operation and maintenance.

-

Take pictures and videos to show how to operate machines

Payment And Delivery

- Before pay deposit

Inquiry--Send Quotation--Confirm order --Proforma Invoice and contract for your esteemed company

- When pay deposit

Pay 30% as deposit by T/T --Prepare machine--bottle cap sample send for our company--Machine will work first in our company and use your bottle sample

- After pay deposit

Take some pictures and videos about machine running and working or engineers, workers of your esteemed company come our company to check it --the balance 70% payment will be cleared before shipment-- After machine arrive in your company , our engineer will instal in your company untill machine can work successfully and stably.