Product

12000 BPH Pure Water Filling Machine

This automatic rinsing, filling and capping machine, could be applicable quantitative filling and capping of drinking water, mineral water, Pure water.

Product Features

Product Details

This automatic rinsing, filling and capping machine, could be applicable quantitative filling and capping of drinking water,mineral water,Pure water. It has functions as follows: Disinfectant rinse, aseptic water rinsing; automatically liquid filling tank, inlet material; feed bottles by air conveyer (or screw convey);automatically rinse, open valve and feed caps; No rinsing without bottles .Compact structure; reasonable design and convenient operation and maintenance. Main machine is adopted frequency speed control, it runs stable and credibility. Material of contacted with product we use high food grade stainless steel. After exchanging changeover parts, it is applicable for different kinds of PET bottle filling.

We adopt advanced touch screen operation and realize human-machine communication. Function of control system as follows: product speed control, automatic stop with faults and take count of output,.etc.

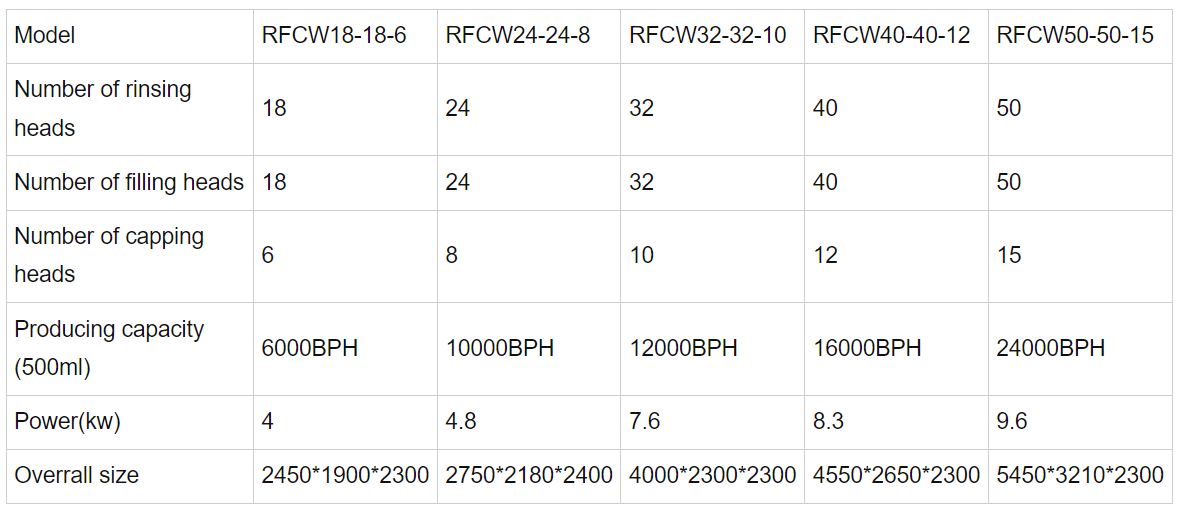

Technical Parameters

Rinser

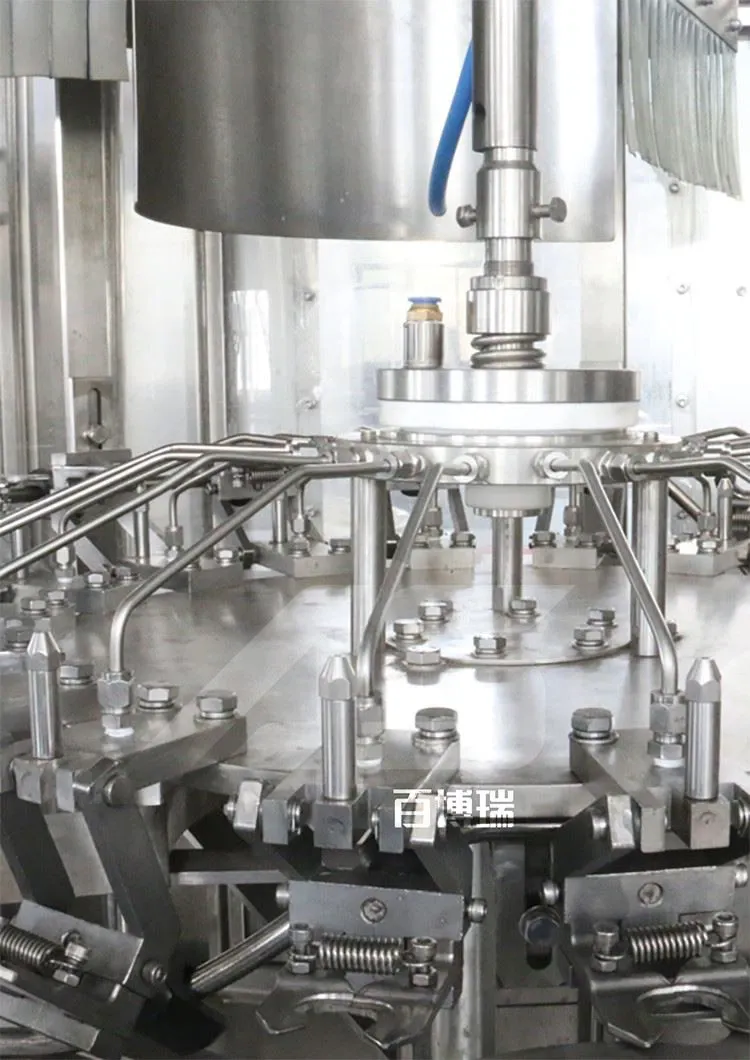

The rotary wheel is a fully sus304 stainless steel welded structure.

The machine applies unique overturning bottle clamp, which is an innovation of our company.This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp.Made of sus304 stainless steel, this bottle clamp is hygienic and durable.

The high efficiency atomizing spay nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and also saves rinsing water.

Transfer starwheel.

Made of stainless steel of superior quality.

Equipped with bottle jam protection device.

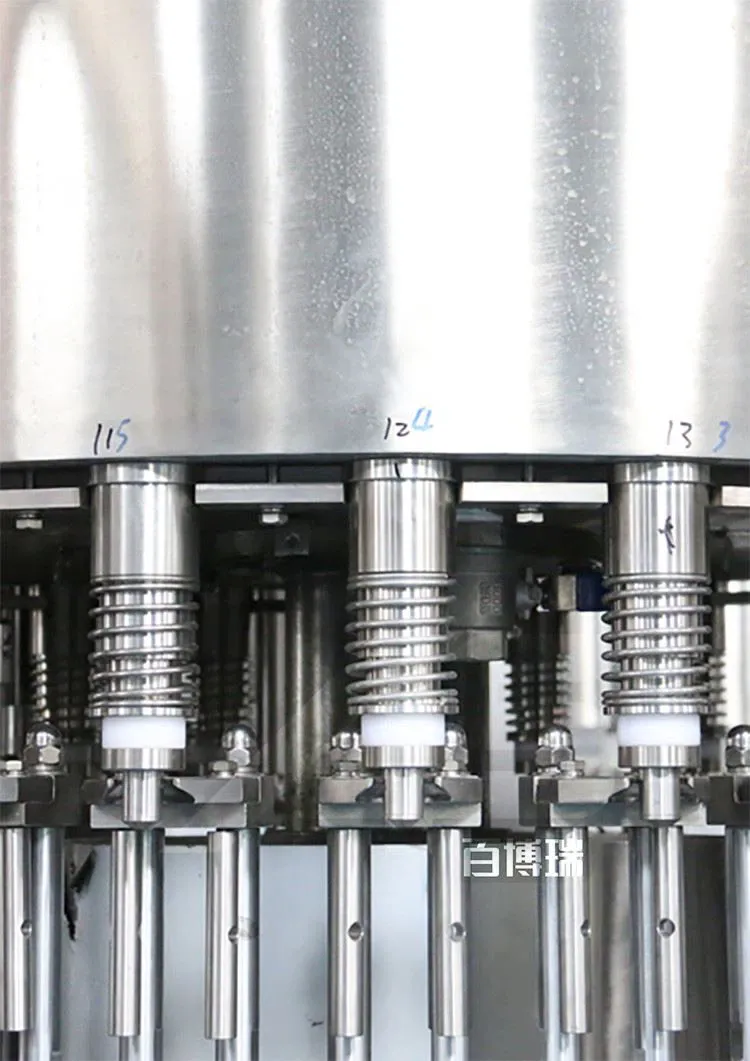

Filler

Mainly composes of bottling barrel, bottling valve, guide rail, lifting device, bottle clamping lift device etc.

Bottle is conveyed to the bottling machine with the clamp plate of starwheel drive, bottling bottle clamp plate supports the bottle neck and rotates together with the bottling, and ascend along the guide rail and then open the bottling valve for bottling, after finishing bottling, it descend and loose the bottling valve, bottling valve may automatically close. Bottle is discharged from the bottling machine along the clamp plate of starwheel drive .

Capper

The capping will be stopped automatically when there is no bottle. When bottles are cramped wrongly or when caps are not available, the machine can be stopped automatically.

Company Introduction

Set up in 2009, Asiastar leads the market in the field of liquid bottling, blow molding, labeling, packaging machinery and process technology for water, juice, carbonated drinks, energy drinks, liquid, beer, edible oil, etc.

We can customize liquid production lines according to customers' demand. Every customer is the result of our proven experience and innovation. We continually focus on providing customers with advanced technology, engineering and facility that are designed with one motto in mind: Ensure you to reach business goals with most optimized planning.

FAQ

Q1: What’s is your shipping service?

A: We can provide services for vessel booking, customs declaration and shipping documents preparation.

Q2. What's your products?

A. Bottled water filling machine, barreled water filling machine, gallon water filling machine, carbonated drink filling machine and water treatment system etc..

Q3:What’s the payment terms?

A:T.T with 30% downpayment,70%before shipment.or L/C at sight.

Q4: May I know what’s the nearest airport from your company?in case I visit your company.

A: First Xuzhou Guanyin Airport, then we drive to pick you up, welcome to visit us.

Payment Term And After-Sale Service

Payment Term

- 30% T/T in advance as deposit , and the balance be cleared before shipment ;

Sample Provide

-

The customer should supply no less than 50pcs samples for each kind of cap and bottle within a week after the contract is signed.

-

If customer without bottle sample yet, need provide the bottle & capper drawing with full dimension details.

Delivery & Packing

- Delivery Time: 30 days after get the bottle & Caps sample or get the bottle & cap dimension.

Coming Document:

- Machine Quality Guarantee

- Complete set install & maintain instruction Book in English language

- Complete Document for customer clearance

Packaging requirement:

-

The special packaging box is according to the immunity standard in China?it suits for long-distance transport, damp proof, rustproof, land way and seaway.

-

Transportation ways: Ocean transportation

Install in Spot

- If our Engineers install in spot

- Installment USD80/day. Person as allowance

- Training fee is free for customer’s workers within the installation period

- The tickets from China to the customer factory and return paid by the customer

- The visa cost, local housing , food, and transfer cost at customer factory paid by the customer

Mechanical Warranty

- Offer 12 months maintenance period to the problem that caused by our design, manufacture and the material quality, and offer the relevant parts and effective service for free for above reason.

- Come with one year’s recommended spare parts.