Product

Asiastar Bottle Sealing Machines

This automatic rinsing, filling and capping machine, could be applicable quantitative filling and capping of drinking water, mineral water, Pure water.

Product Features

Product Description

Full Automatic 3 in 1 Complete PET Bottle Pure Mineral Water Filling Production Machine

This automatic rinsing, filling and capping machine, could be applicable filling and capping of drinking water, mineral water, Pure water. It has functions as follows: Disinfectant rinse, aseptic water rinsing; automatically i liquid filling tank, inlet material; feed bottles by air conveyer; automatically rinse, open valve and feed caps; not rinse, open valve and feed caps without bottles .

Compact structure; reasonable design and convenient operation and maintenance. Main machine is adopted frequency speed control, it runs stable and credibility. Material of contacted with product we use high food grade stainless steel. After exchanging changeover parts, it is applicable for different kinds of PET bottle filling.

Whole Machine Outlooking

Washing Heads

Bottle washing clamp rotates with the upper rotary plate, and open the bottle mouth clamp with elastic distortion when contacting the bottle feeding starwheel, which can clamp the bottle neck, then overturns at 180° along the guide rail, bottle mouth may become downwards for cleaning and drying the bottle with water, then overturn for 180°, bottle mouth becomes upwards and then conveyed with the starwheel.

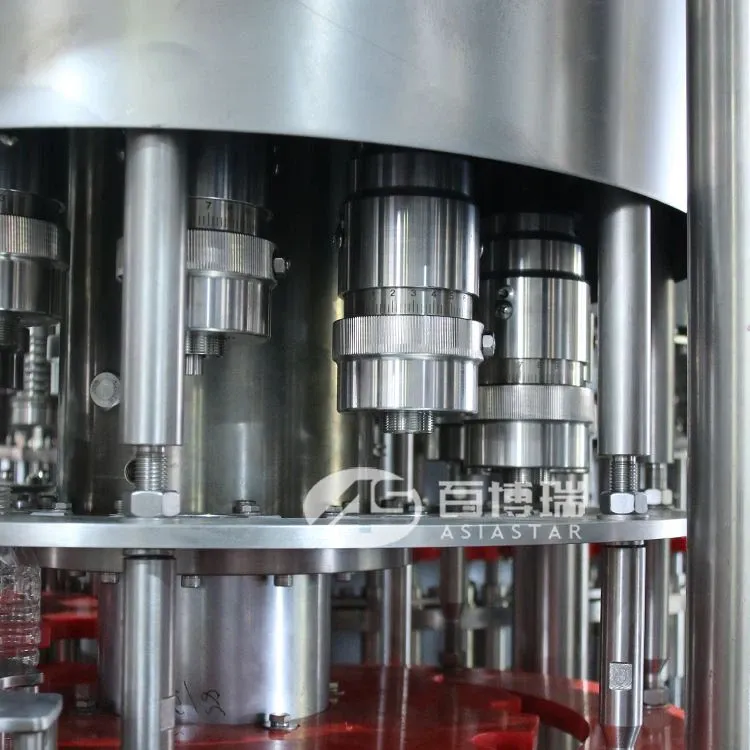

Filling Heads

High precision filling nozzle, PLC variable signal control, All 304 stainless steel contact parts & liquid tank, easy to clean No bottle no filling

Capping Heads

Bottle is conveyed into the capping machine and then is clamped with the bottle clamping block; the cap is arranged by the cap arranging mechanism and then is delivered to the cap separating mechanism from the lower cap tank; cap separating mechanism can separate the caps, and capping head may ascend and remove the cap and press it onto the bottle mouth with cam; under the drive of gear, capping head tighten the cap on the bottle mouth along the shaft, and keep constant capping moment; the well capped bottle is delivered out with 4# starwheel. The capping machine is connected with cap separating mechanism, lower cap tank, cap arranging mechanism with harmonious combination through several movements for delivering bottle, delivering cap, holding cap and capping.

FAQ

Q: How long time for installation?

A: Subject to machines and the situation in your factory. If everything is ready, it will take about 10 days to 25 days.

Q: What is your payment term?

A: 30%T/T in advance as deposit, rest should be paid before shipping. L/C is supported also.

Q:When can I get my machine after I paid?

A:Normally production time is around 30 -60days,the exactly depend on what kind of machine you order.The shipping time is based on your destination port.

Q: How about the spare parts?

A: After we deal down all the things , we will offer you a spare parts list for your reference.

Asiastar Beverage Machinery Co.,Ltd