Product

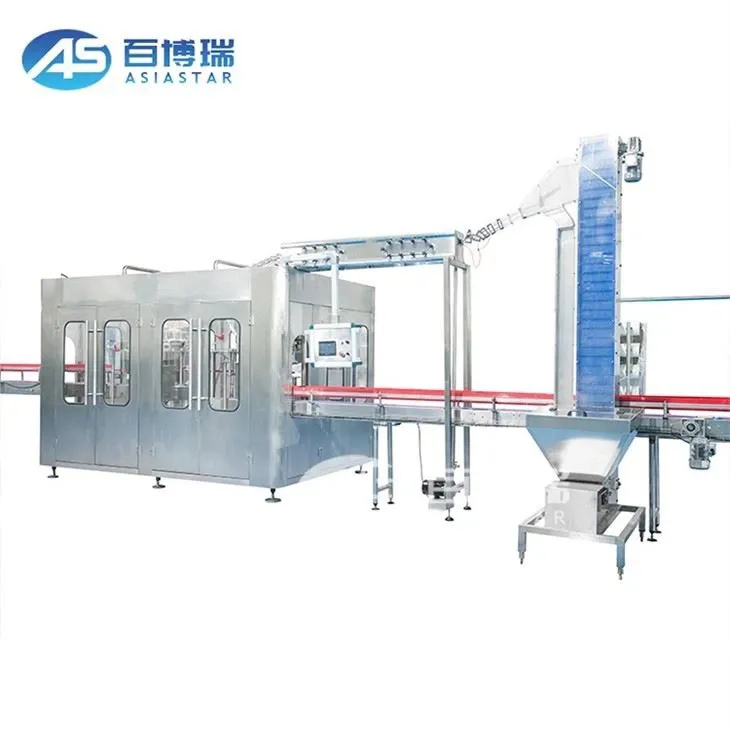

Filling And Capping Machine

The hanging bottleneck design keeps the bottle stable under high-speed motion, and it can easily meet the production of different types of bottles by replacing a few parts.

Product Features

Product Description

This machine adopts advanced gravity filling technology, and the filling is fast, stable and accurate.

This machine adopts advanced technologies such as man-machine interface touch screen and PLC program control.

All parts in direct contact with water are made of high-quality stainless steel, and key electrical components are from internationally renowned companies such as Mitsubishi, Siemens, and Omron.

Washing parts

The bottle inlet is equipped with a pneumatic device to control the bottle inlet to prevent the bottle from entering the host.

The water inlet pipe of the bottle washer is equipped with a pressure gauge and a pressure regulator valve.

Manually adjust the lift to suit bottles of different heights.

Install a water receiving tray to recycle the flushing water.

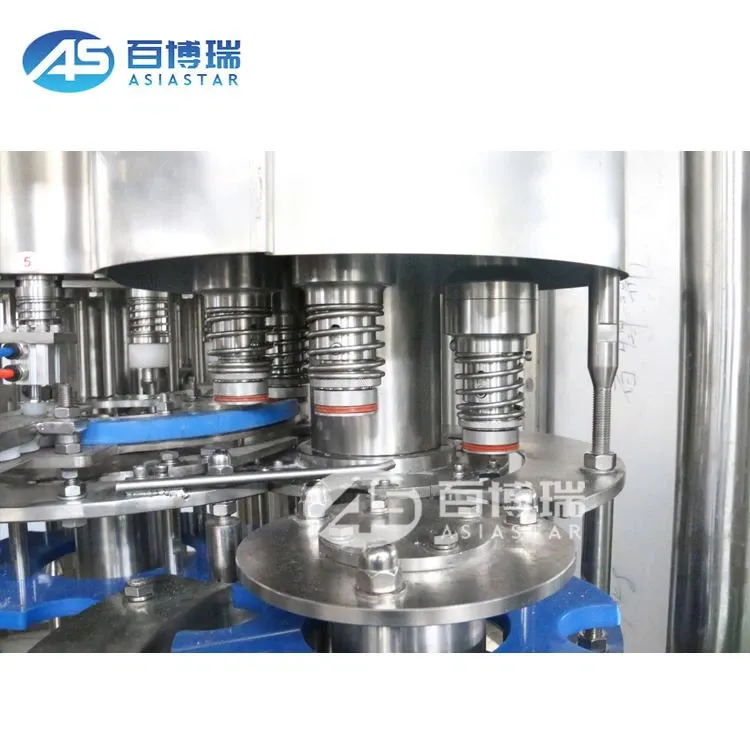

Filling Parts

The bottle guide system has a simple structure and can be quickly and easily replaced according to the bottle type. The whole machine adopts a bottleneck clamping structure for conveying.

The whole machine is automatically controlled by PLC. Faults are displayed online, such as bottle blockage, missing cover, etc.

Automatic control of the materials in the filling tank. The height of the liquid level is detected by the liquid level sensor to ensure the stability of the liquid level and the reliability of the filling.

The key parts and electrical components of this machine are all imported products.

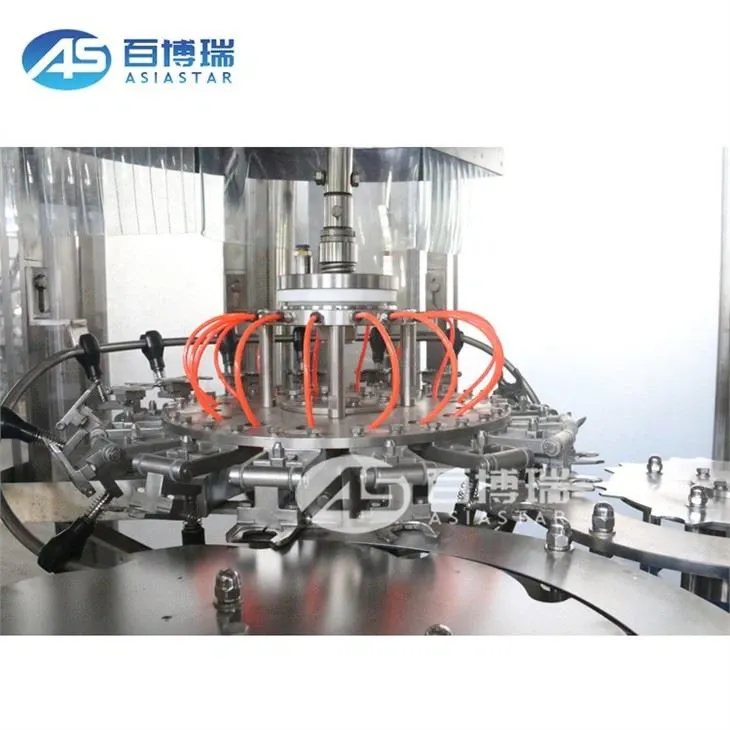

Capping parts

The capping machine drives the turntable to rotate through the reducer. The lid leaves the hopper from the lid outlet under the action of centrifugal force. The air outlet is provided with a front and back cover separation device. When the shadow cover passes by, the shadow cover automatically falls into the return pipe, and the shadow cover is automatically blown into the hopper by the wind. Only the positive cover can enter the slideway smoothly. When the positive cover plate enters the slideway, it can smoothly enter the cover feeding plate. In order to prevent accidents, an anti-reverse cover dial is arranged on the slide rail to ensure that the cover that enters the feeding cover plate is correct. A pair of photoelectric switches are also arranged on the slider, and the host will be stopped immediately when it is detected that there is no cover. In order to effectively remove the broken cover without the anti-theft ring and the remaining cover plate when cleaning the hopper, a movable discharge port is provided directly opposite the hopper outlet to meet this function.

This machine adopts a centralized lubrication system, which can easily lubricate all lubrication points.