Product

Pure Water Bottling Machine

The mono-bloc machine is integrated with rinsing, filling and capping together;

Product Features

Product Description

The mono-bloc machine is integrated with rinsing, filling and capping together;

The bottle enters into the rinsing part of three-in-one machine through air conveyor. The gripper installed on the rotary disk catches bottle and turns it over 180 degrees and makes the bottleneck face ground. In the special rinsing area, the nozzle on the gripper sprays water to rinse bottle in wall.

After rinsing and draining, the bottle turns over 180 degrees along the guide rail and make the bottleneck faces sky. Then rinsed bottle is transferred to the filling part through poking bottle star-wheel. The bottle that enters into the filler is hold by neck holding plate. The filling valve acted by the cam can realize up and down. It adopts pressure filling way. The filling valve opens and begins filling when it moves down and touches the bottleneck, the filling valve move up and leave the bottleneck when it finishes filling.

The full bottle is transferred to the capping part through hold neck transition poking wheel. The stop screwing knife holds the bottle neck, keeps bottle upright not rotating. The screw capping head keeps in revolution and autorotation. It can finish a whole capping course including catching, pressing, screwing, discharging through the action of the cam. The full bottle is transferred to bottle outlet conveyor to the next process through poking wheel. The whole machine is enclosed with windows, the height of enclosed window is higher than the peak of the 3 in 1 machine, in the bottom of the enclosed window has return air outlet.

Rinsing Part

Pure water mineral water bottling machine washing part:

The rotary wheel is a fully SUS304 stainless steel welded structure.

The machine applies unique overturning bottle clamp. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp. Made of SUS304 stainless steel, this bottle clamp is hygienic and durable.

The high efficiency atomizing spay nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and also saves rinsing water.

All sliding bushes of lifting device use Igus (Germany) anti-corrosion maintenance free bearing.

The rinser is driven by driving system positioned inside machine frame via gear transmission.

Transfer Starwheel

Made of stainless steel of superior quality.

Equipped with bottle jam protection device.

Filling Part

Rotary wheel fully made of stainless steel sus 304.

Gravity filling method.

Filling valves are made of sus316l.

Filling valves are reasonably structured with accurate filling.

Bottles go up and down in the function of cam through elevator, to process filling with contact to bottle-mouth.

Filler is driven through gears inside the machine frame.

Link-wheels in rinser, filler and capper are transported in ringed support of bottle-neck

Capping Part

Pure water mineral water bottling machine capping part:

Cap distributing chute is equipped with reverse cap stop and reverse cap pick-out mechanism.

Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute.

The capper is equipped with inlet bottle detection switch.

Centrifugal way of cap arranging is adopted to reduce damage of caps.

A cap inspecting system is applied to control on-off of elevator.

Cooperated Brand

Related Products

Air conveyor

(1) The Air conveyor material is SUS304 material

(2) It adopts automatic PLC control

(3) Contactor, breaker is Schneider

(4) Cylinder /solenoid valve is Airtec

Cap Elevator (Cap Sterilizer Tank/ Cap Sterilizer)

The worker only needs to put the cap in the cap box, and then the cap will sterilized by sterilizing water and then transfer the caps to the capping part. Also, we have the cap sterilizer tank.

Gantry Palletizer

The palletizer puts the film packs in the container on the pallet according to a certain arrangement and stacks them automatically. It can be stacked in multiple layers and then pushed out to facilitate the forklift to transport to the warehouse for storage. This equipment adopts PLC+touch screen control to realize intelligent operation management, simple and easy to master. Can greatly reduce labor and reduce labor intensity.

FAQ

Q1: If I want to buy a machine, what information do I need to tell you, do you need from me?

A:1. What kind beverage you want to produce?

-

Bottle volume? 250ml, 330ml, 500ml, 750ml, etc.?

-

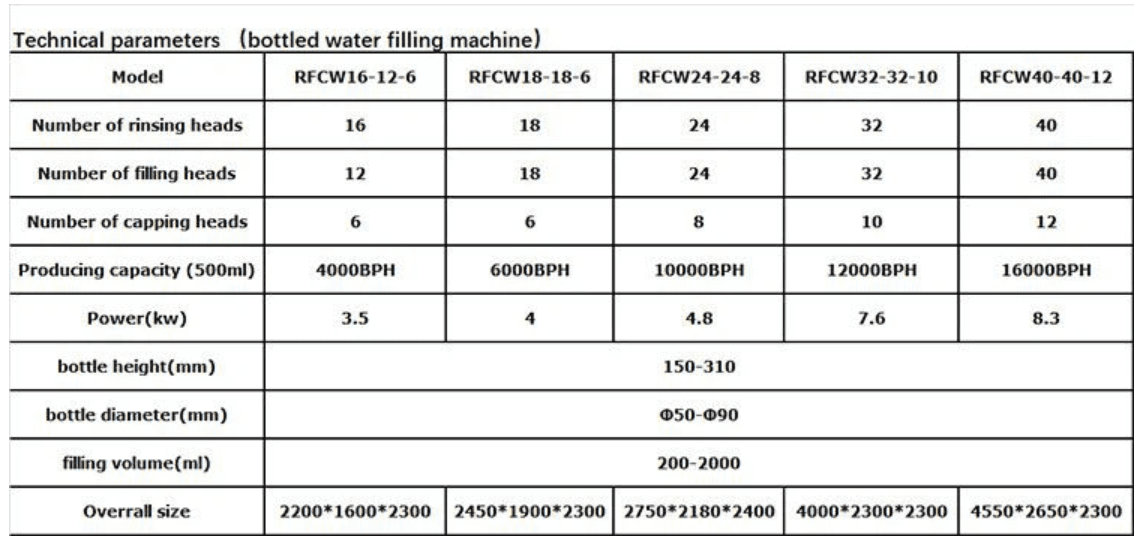

Producing capacity requirement? How many bottles per hour?

4.Raw water analysis report .

5.Voltage and altitude.

Q2:What kinds of product you supply?

A: 1. Drink water/juice/carbonated drink filling line.

-

5 gallon/20L/ can beverage/glass bottle beverage filling line

-

Water treatment system.

-

Bottle blowing making machine.

-

After packing system(label machine, PE film shrink packing machine, carton machine)

Q3:How can you ensure the machine's quality after we put the order?

A:Before the delivery, we will send you machine's pictures and videos, or you can come to us to have the quality checking by yourself, or by the third party inspection organization contacted by your side.

Q4:How about the after-sale service?

A:(1)More than 12 hours after-sale online service one day.

(2) We have engineers available to service machinery overseas.The service charge, include: service fee USD80/day, VISA fee, board round-trip ticket, room and eat in are buyer's side.

Q:5 How can I get more related information of your machines?

A: Just feel free to contact us. We will send you pictures or videos for your reference. And our colleague will give you someprofes.