Product

Reverse Osmosis Water Treatment Device

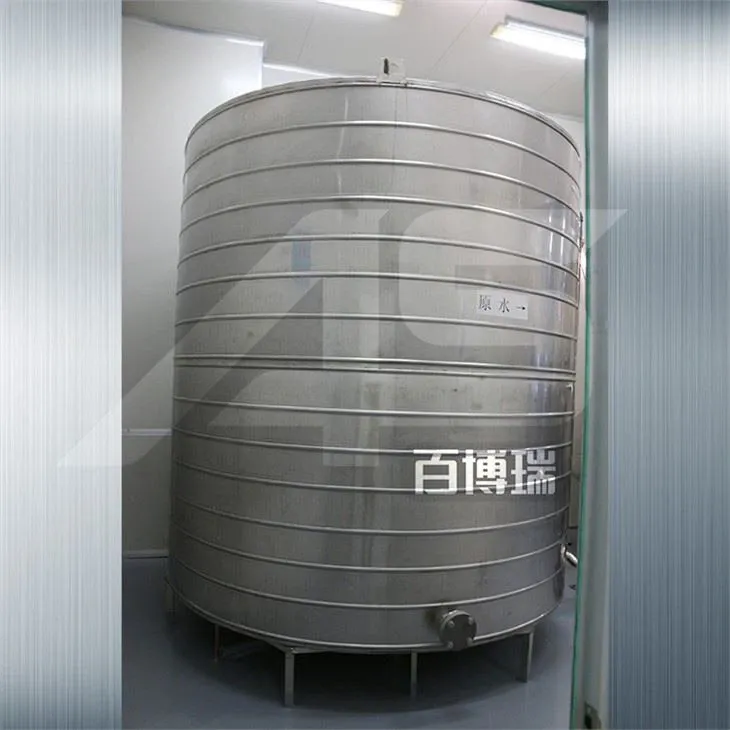

Water treatment system refers to the measures taken to make the water quality meet certain use standards.

Product Features

Product Description

Water treatment system refers to the measures taken to make the water quality meet certain use standards. The physical characteristics of water, such as temperature, color, transparency, odor and taste, are filtered or treated so that water can be used directly for drinking or other purposes.

Flow Chart

Raw water pump: connect to raw water,we supplier the best supplier Nanfang pump.

Quartz sand filter: Quartz sand as a filter medium can intercept and remove suspended matter effectively, organic matter, colloidal particles, microorganisms, chlorine, odor and some heavy metal ions in water under certain pressure, so as to reduce water turbidity.

Active carbon filter: It can filter chlorine content in water: <0.1PPM, and has significant effect on odor, organic matter, colloid and iron in water. It can also reduce turbidity, chroma of water, purify water quality and reduce pollution.

Sodium filter: Sodium filter (softener) is used to remove calcium and magnesium ions from water. When calcium and magnesium ions in water are exchanged by sodium ion, carbonate scale and sulfate scale are not easily formed in water, thus softening water can be obtained.

Precision filter: It adopts PP filter membranes which has high filtering precision, less than 0.1um particles, strong ability of intercepting pollution and long service life.

Reverse osmosis: it is composed of reverse osmosis membrane (RO), high pressure pump and washing system to protect the reverse osmosis membrane. It can intercept substances larger than 0.0001 micron. It is the finest water filter. It can effectively intercept all dissolved salts and organic substances with molecular weight greater than 100, and allow water molecules to pass through.

UV: After the RO system, the bacteria in the water are eliminated by using the UV sterilizing lamp.

Ozone Sterilizer: Its function is to mix ozone into water.

In order to achieve the ideal sterilization effect of ozone, ozone mixing tower is used to mix ozone and water fully under certain pressure and time.

Ozone generator: Ozone is a widely recognized high-efficiency disinfectant in the world. Chemical property is particularly active, is a strong oxidant, at a certain concentration can quickly kill bacteria in water and air.

Water Filling Machine

Automatic Sleeve Labeling Machine

Automatic Shrink Wrapping Packing Machine:

Delivery Date And Payment Method

-

Delivery date: After the contract is effective and 30% of the total contract amount is received, the delivery is usually within 60 working days

-

Payment method: 30% of the total amount of the down payment contract is the effective date of the contract. Before the supplier ships the goods (after the buyer has inspected the goods at the supplier's site), the buyer will pay 70% of the payment, and the equipment will leave the factory. Before the supplier technician arrives at the demand side, water, electricity, gas, bottles, caps, labels and supporting facilities are in place.

Technical Services

- Installation, commissioning

? After the equipment is delivered to the user's workshop, the user should position the equipment in accordance with the provided floor plan.

? The company will send experienced technicians to guide the installation, commissioning and trial production of equipment.

? Our company will adjust the equipment to the design capacity within the planned time, the entire line acceptance production capacity is not less than 86% of the design capacity, and it will run continuously for four hours.

? During commissioning, the company is responsible for providing corresponding spare parts and accessories free of charge. The buyer shall be responsible for the board and lodging expenses of the commissioner.

- Staff training

? Our company is responsible for providing free technical training to the buyer. The training content includes equipment structure and maintenance, equipment control and operation, etc.

? Training can be carried out at the buyer’s site. Our company will appoint qualified technical personnel for guidance and formulate corresponding training programs.

? Through training, the customer’s technical personnel should be able to master the relevant operation and maintenance skills, adjust the process more proficiently, and handle various failures in a timely manner;