Product

Water Treatment Solutions

This pure water treatment machine reverse osmosis syetem is for producing drinking water, foods factory, beverage factory, fruit&vegetable factory etc.

Product Features

Product Description

This pure water treatment machine reverse osmosis system is for producing drinking water, foods factory, beverage factory, fruit&vegetable factory etc. The machine is integrated into a group, the assembly and transportation are rather convenient. It's simply operation and has long lifespan.

-

Quartz sand filter: to remove the particulate solids from waste water; it totally can be washed, so can be replaced every 6 month .

-

Active carbon filter: to remove the chlorine and the smell of water; it totally can be washed, so can be replaced every 6 month .

-

Sodium filter: to soften the water , and exchange the calcium ion & magnesium ion ; there's no need to change it, as it is completely recycled .

-

Precise filter: to clear the granules bigger than 5micron and also protect the reverse osmosis device membrane, it can be changed every 3 month to half a year.

-

RO device: to clean the Particle, colloid, bacteria, heat source and organic matter in the water, used for pure water; the filter membrane needs to be replaced one time every year.

Water Treatment System Producing Process

- Raw water tank

- Raw water pump

- Quartz sand filter

- Active Carbon filter

- Sodium filter Precise filter

- Reverse osmosis device

- Ozone sterilizer

- UV sterilizer

- Pure water tank

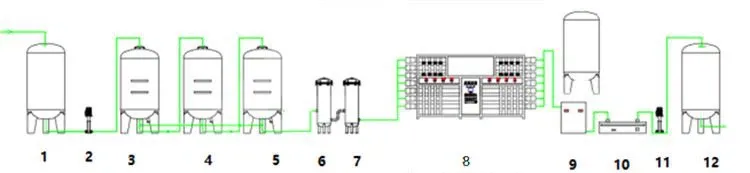

Flow Chart

1.Raw water tank 2.Raw water pump 3.Quartz sand filter 4.Active carbon filter 5.Sodium filter 6.Micron 5um filter 7.Micron. 1um filter 8.RO device 9.Ozone sterilizer &Ozone tower 10.UV sterilizer 11.Pure water pump 12.Pure water tank

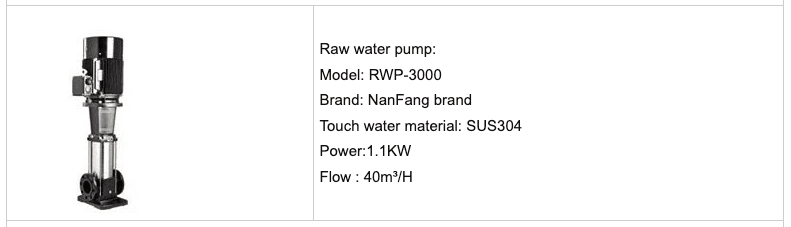

Raw water pump

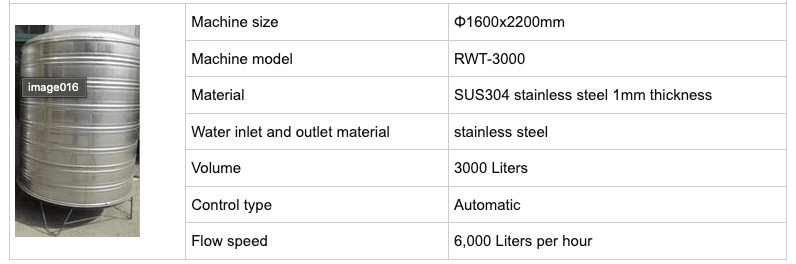

Pure water tank (Customer no need)

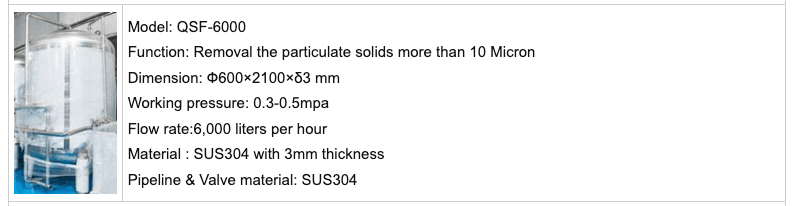

Quartz sand filter

Active carbon filter

Sodium filter system

Precise filter

RO device

Ozone sterilizer (including ozone tower)

UV sterilizer

Our Company

ASIASTAR as one of the major beverage machine manufacturers in China, was established in 2009. With more than 10 years producing and exporting experience, we can offer complete solution to design, manufacture, pack, transport, install , maintain the beverage packing machines according to our customer's requirements.

Delivery Date And Payment Method

After the contract is effective and 30% of the total contract amount is received, the delivery is usually within 60 working days.

30% of the total amount of the down payment contract is the effective date of the contract. Before the supplier ships the goods (after the buyer has inspected the goods at the supplier's site), the buyer will pay 70% of the payment, and the equipment will leave the factory. Before the supplier technician arrives at the demand side, water, electricity, gas, bottles, caps, labels and supporting facilities are in place.

Staff Training

(1) Our company is responsible for providing free technical training to the buyer. The training content includes equipment structure and maintenance, equipment control and operation, etc.

(2) Training can be carried out at the buyer’s site. Our company will appoint qualified technical personnel for guidance and formulate corresponding training programs.

(3) Through training, the customer’s technical personnel should be able to master the relevant operation and maintenance skills, adjust the process more proficiently, and handle various failures in a timely manner.